Scientists at Caltech have created a brand new approach that permits exact management over the composition and construction of metallic alloys by 3D printing. The strategy builds on the workforce’s earlier work with hydrogel-infusion additive manufacturing (HIAM), extending it to create alloys with customized percentages of various metals. The analysis was printed within the journal Small, with Thomas T. Tran as lead writer and Rebecca Gallivan as second writer.

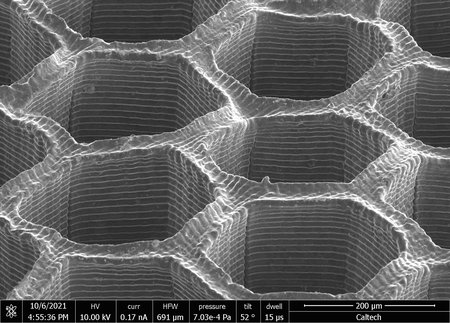

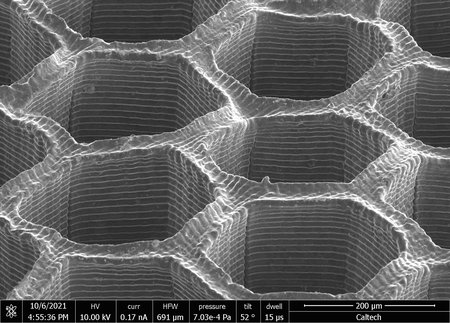

The method begins with 3D printing an natural hydrogel scaffold, which is then infused with metallic ions from liquid metallic salt options. Scientists burn away the natural materials in a course of known as calcination, leaving metallic oxides behind. Within the last step, known as reductive annealing, the fabric is heated in a hydrogen atmosphere to take away oxygen and type the specified metallic alloy construction.

“The composition will be diverse in no matter method you want, which has not been attainable in conventional metallurgy processes,” says Julia R. Greer, the Ruben F. and Donna Mettler Professor of Supplies Science, Mechanics and Medical Engineering at Caltech. The workforce demonstrated this management by creating copper-nickel alloys with completely different ratios, discovering {that a} Cu12Ni88 alloy was almost 4 instances stronger than a Cu59Ni41 alloy.

Evaluation utilizing transmission electron microscopy revealed that the HIAM course of creates extra uniform crystal buildings in comparison with different strategies. The approach additionally leaves tiny oxide inclusions throughout the alloys that contribute to their power. “Due to the complicated methods during which metallic is shaped throughout this course of, we discover nanoscale buildings wealthy with metallic–oxide interfaces that contribute to the hardening of our alloys by as much as an element of 4,” Tran says.

The analysis reveals that alloy power is determined by each grain dimension and composition, difficult earlier assumptions about metallic power components. The work was supported by the US Division of Power’s Fundamental Power Sciences program and a Nationwide Science Basis graduate fellowship.

Supply: caltech.edu