The MyMR line of AMRs is designed to dynamically adapt to structure modifications. Supply: Comau

Comau S.p.A. this week launched its MyMR household of autonomous cell robots, or AMRs. The economic automation supplier debuted the system at Automatica 2025 in Munich, Germany.

“The worldwide debut of MyMR robotic household at Automatica underscores our dedication to redefining intralogistics by clever, cell automation,” stated Nicole Clement, the chief enterprise unit chief at Comau. “AMRs and AGVs are anticipated to change into one of many fastest-growing segments inside industrial automation, reaching a CAGR of 31% by 2027, in line with our estimates.”

“By including this important automation enabler inside our huge product portfolio, Comau now has an entire, built-in ecosystem to assist our prospects improve flexibility, security, and effectivity throughout the intralogistics worth chain,” she stated.

Turin, Italy-based Comau engineered the brand new line to fulfill the growing calls for of intralogistics throughout manufacturing, warehousing, logistics, and extremely automated environments. The firm stated the MyMR platform addresses key challenges similar to labor shortages, materials dealing with inefficiencies, and security considerations with a modular, scalable, and absolutely autonomous system.

MyMR line consists of three new fashions

MyMR presents superior options similar to clever fleet administration, real-time impediment avoidance, and line integration. This units it other than conventional automation programs or handbook dealing with processes, stated Comau.

With three distinct fashions providing payload capabilities of 300, 500, and 1,500 kg (661.3, 1,102.3, and 3306.9 lb.), Comau stated its AMRs help a broad vary of logistics duties. This consists of something from production-line provide to warehouse automation and kitting.

The robots’ superior navigation system permits them to dynamically adapt to structure modifications. Comau stated this will improve flexibility and operational uptime with out requiring devoted infrastructure or predetermined trajectories.

Designed to help diversified industries, Comau stated MyMR displays its imaginative and prescient of the cell, digitally linked manufacturing unit. The platform allows protected human-machine collaboration, empowering decentralized and agile manufacturing flows whereas making certain that AMRs and employees function aspect by aspect.

Along with the three AMR fashions of the MyMR household, Comau presents customary attachments similar to lifters, conveyors, shelving, and different equipment. With these equipment, prospects can tackle a full vary of warehouse automation and intralogistics wants, it stated.

Moreover, MyMR robots could be transformed from an AMR to an automatic guided car (AGV) due to its superior software program configuration, defined Comau. This permits extra flexibility and performance as prospects’ wants change.

Comau unveils cobots, exoskeletons

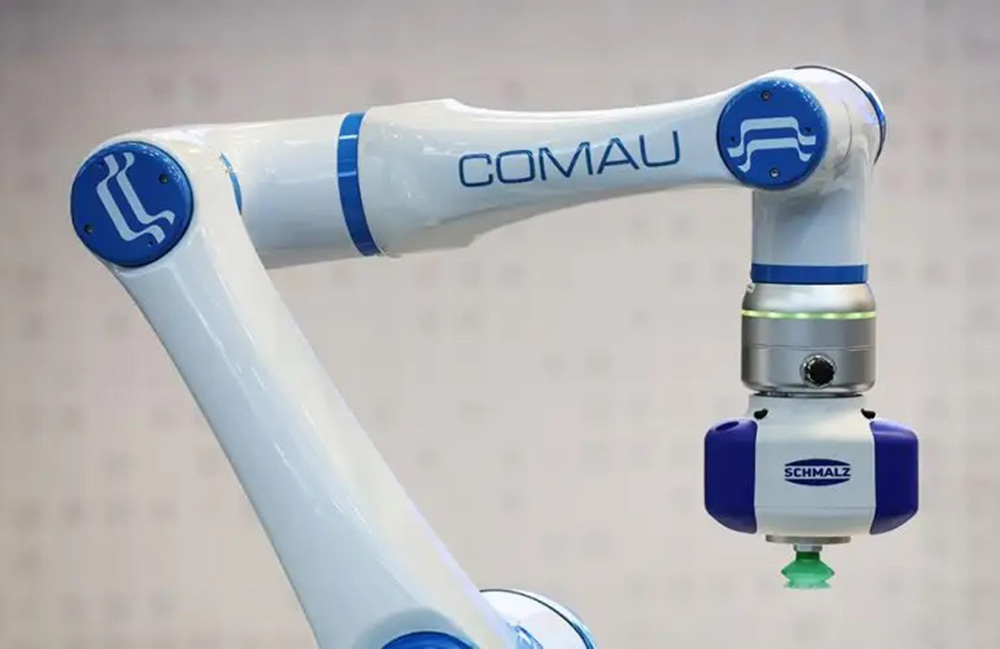

Along with its new household of AMRs, Comau additionally unveiled its new MyCo household of collaborative robots. The MyCo lineup options six distinct cobot fashions with payload capacities starting from 3 to fifteen kg (6.6. to 33 lb.) and reaches between 590 and 1,300 mm (23.2 to 51.1 in.).

The corporate stated it designed the road to fulfill the rising international demand for versatile, protected, and easy-to-use collaborative automation. It stated MyCo is appropriate for warehousing, intralogistics, packaging, arc welding, and light-weight meeting.

The cobots’ sturdy but light-weight development helps straightforward relocation and redeployment, whereas the IP66 safety ensures dependable efficiency even in demanding circumstances, Comau claimed.

As well as, Comau debuted two exoskeletons on the present. The MATE-XT upper-back exoskeleton and the MATE-XB lower-back exoskeleton. The corporate stated it designed the programs to help the physique throughout bending, lifting, overhead, and repetitive duties.

Comau has designed and developed automation for 50 years. Its portfolio consists of merchandise and programs for car manufacturing, with a powerful presence in e-mobility. The firm additionally presents superior robotics and digital programs, in addition to challenge administration and consultancy companies.

In April, Comau stated it is going to purchase Automha S.p.A. from Trasma S.r.l. The Italian firm has greater than 40 years of expertise growing automated storage and retrieval programs (ASRS) to optimize effectivity and reliability throughout the warehousing and intralogistics industries.