Overview

Revopoint’s MetroX scanner represents a shift within the firm’s portfolio into the realm {of professional}, metrology-capable 3D scanning.

Not like earlier scanners within the POP collection, MetroX makes use of a number of blue laser traces to seize high-fidelity level cloud knowledge, even on problematic surfaces like shiny black plastic or uncoated metallic (though some spray may be wanted often).

The addition of full-field scanning mode additionally brings a degree of flexibility usually seen in dearer techniques, letting customers seize geometry throughout bigger objects in a single go.

The scanner boasts a single-frame accuracy of 0.03 mm, and a volumetric accuracy of 0.03 mm + 0.1 mm × L (m), placing it within the ballpark of what’s thought-about metrology-grade by many industrial customers. It does this at a fraction of the value usually related to high-accuracy scanning techniques.

It’s powered totally by way of USB (no battery), and whereas that makes it much less versatile in area use in comparison with the POP 3 Plus, the tradeoff is a way more secure energy and knowledge hyperlink. These are important for capturing correct and repeatable scan knowledge.

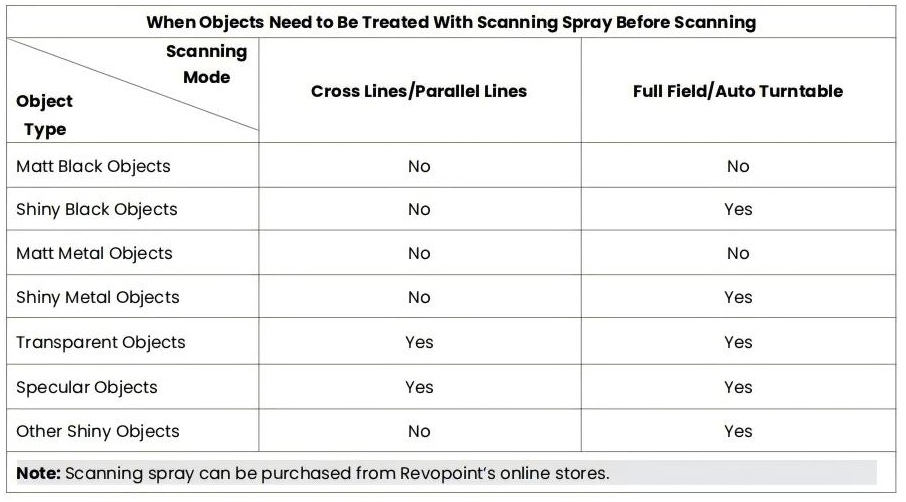

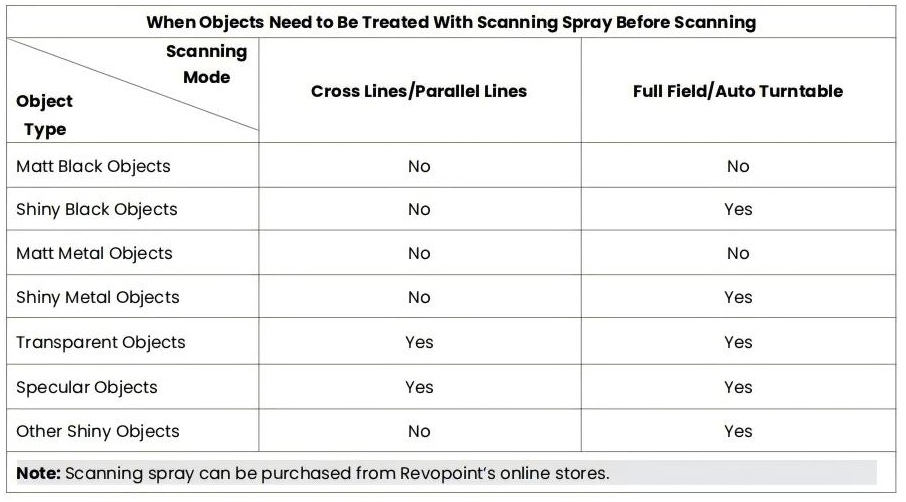

The desk beneath exhibits which modes are finest suited to scanning several types of surfaces. We examined all of them, with various levels of success.

MetroX Choices

The MetroX is offered in two kits, the primary being the “Normal Version” containing the scanner, tripod, dual-axis turntable, energy provide, and all of the cables, all inside a candy aluminium case.

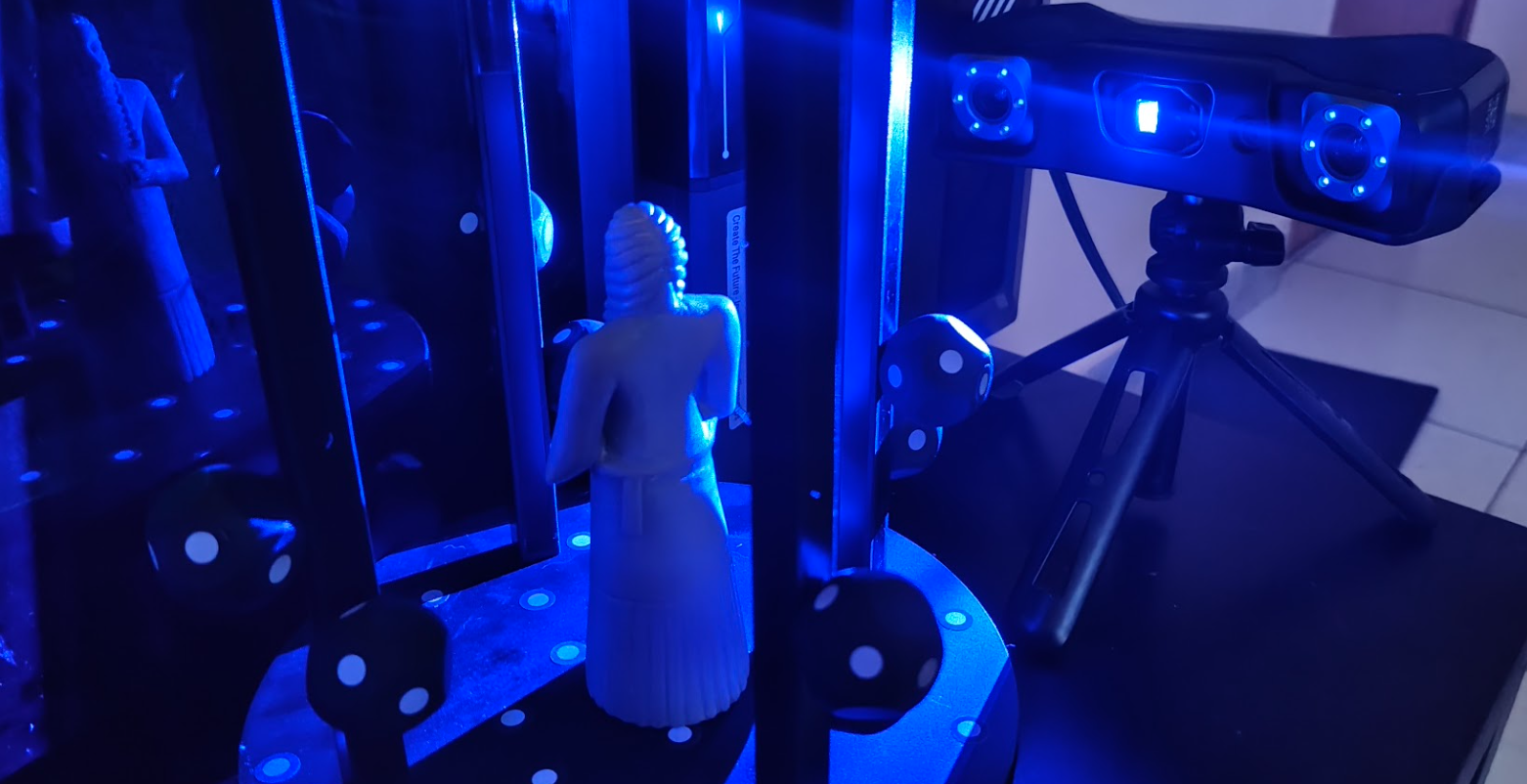

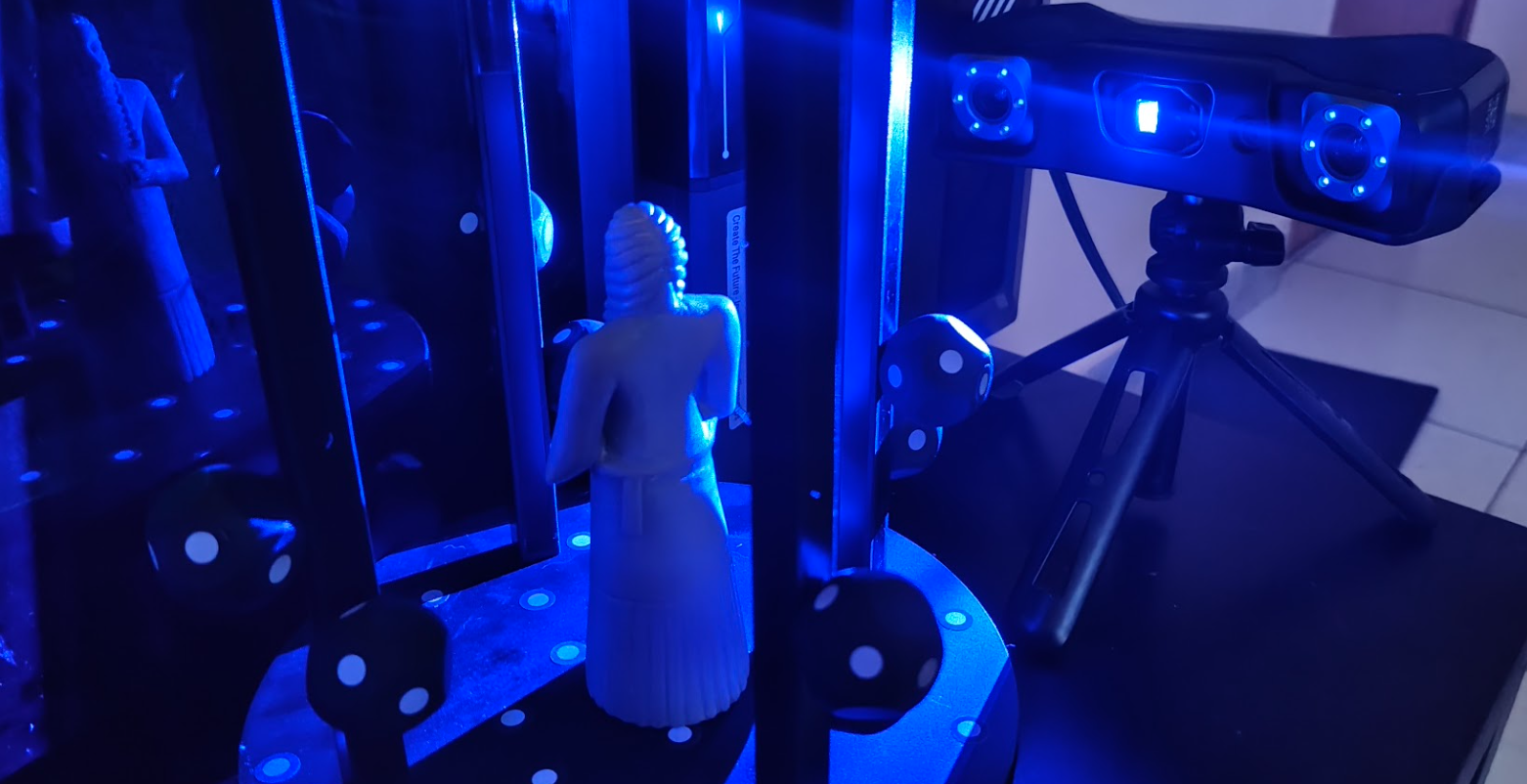

The second possibility (which we reviewed) is the “Superior Version” which is principally every little thing within the Normal Version, plus a Marker Block package. The Marker Block package comprises quite a lot of plastic shapes with markers on and magnets on the base. As well as it comprises for threaded pillars (known as “bar markers”, which could be screwed into the turntable high to offer some fixing factors for the blocks (or extra stickers) within the z-axis.

You’ll be able to see these pillars mounted to the turntable within the picture beneath.

Revopoint Software program

In case you have any of the opposite Revopoint scanners, you’ll probably have a duplicate of their scanning software program (RevoScan) put in in your pc.

To make use of the MetroX, you’ll need to obtain the precise model which was developed for the MetroX. It’s referred to as RevoScan MetroX, it’s free, and you’ll find it on the Revopoint software program web page.

Functionally, it’s virtually equivalent to the unique RevoScan software program, solely the MetroX model permits the completely different scanning modes within the new scanner. So in case you have gotten used to the pointcloud era, mesh creation and modifying within the earlier software program, then you definitely received’t have any issues switching to this new model.

One minor gripe that I do have in regards to the new model, is that it doesn’t have any options for taking measurements from the purpose cloud knowledge. Provided that this new scanner is touted as “metrology-grade”, you’ll suppose that “measuring stuff” can be an necessary function to incorporate. However nope. It ain’t there. If you wish to measure something out of your level cloud or mesh, you’ll have to export it into one thing else.

One other piece of software program of curiosity is the Revo Assistant. Revo Assistant is a smartphone app for IOS and Android, that permits management of the automated turntable. That is fairly helpful to have, as a result of relying on how your turntable is positioned, it could possibly be a bit of tough to entry the bodily buttons to tilt or change path of the turntable.

Now, with the app put in, it makes life a bit of simpler, offering you don’t thoughts having to disconnect the turntable out of your pc’s BluTooth each time you need to use it.

Anyhoo, with all of the software program put in and the scanner setup, on with the testing!

We’ve divided the testing evaluations into two essential sections, one for structured gentle modes, and one for laser line scanning.

Structured Mild Scanning Modes

Each Full Subject and Auto Turntable scanning modes within the Revopoint MetroX make the most of blue structured gentle projection know-how. Structured gentle needs to be your mode of alternative with the MetroX, when velocity and texture matter greater than hardcore accuracy on tough surfaces.

Shade scanning will also be achieved due to the devoted RGB digicam, though this could solely be utilized in auto turntable mode. It needs to be famous that the function scan mode can be solely accessible in auto turntable and full area modes solely. Marker mode will also be used with these modes.

Marker Scan (Auto Turntable mode – coloration)

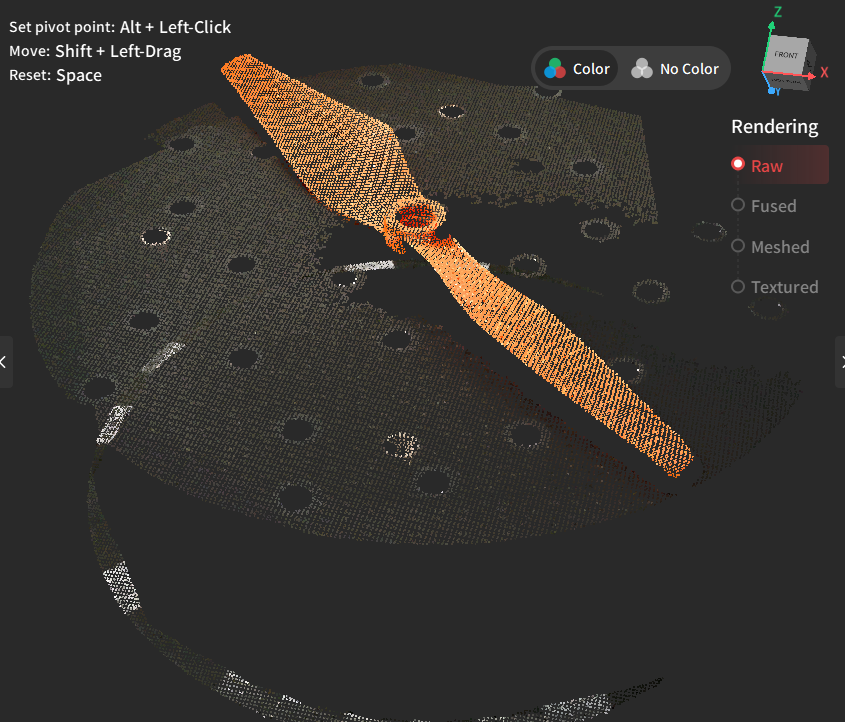

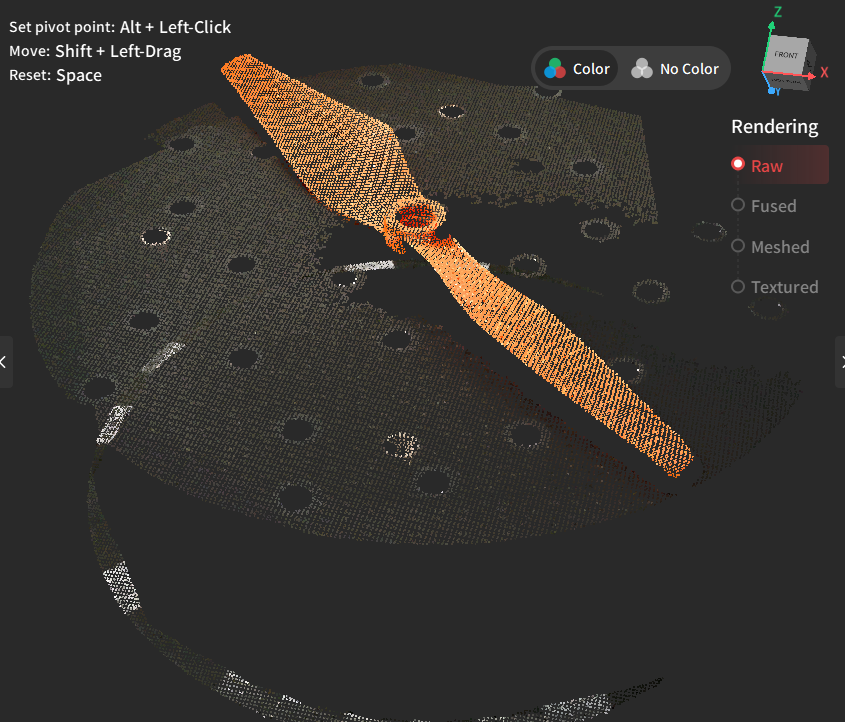

The primary check we did was on a drone propeller. It has some good curved geometry and a few sharp options on the main and trailing edge, so what higher approach to begin testing a metrology-grade scanner?

Not desirous to cowl the propeller in markers, we opted for marker scan (in coloration) utilizing the present markers on the turntable. It scanned high quality, though merging the 2 sides collectively was tough, because the merging function requires 30% overlap between scans to work – and provided that the propeller is so skinny, it was not preferrred. However this isn’t the fault of the scanner or software program, merely of the geometry.

As we are going to see later, the merging function works high quality, so long as you may have a scanning merchandise that isn’t so skinny it may’t stand on its sides.

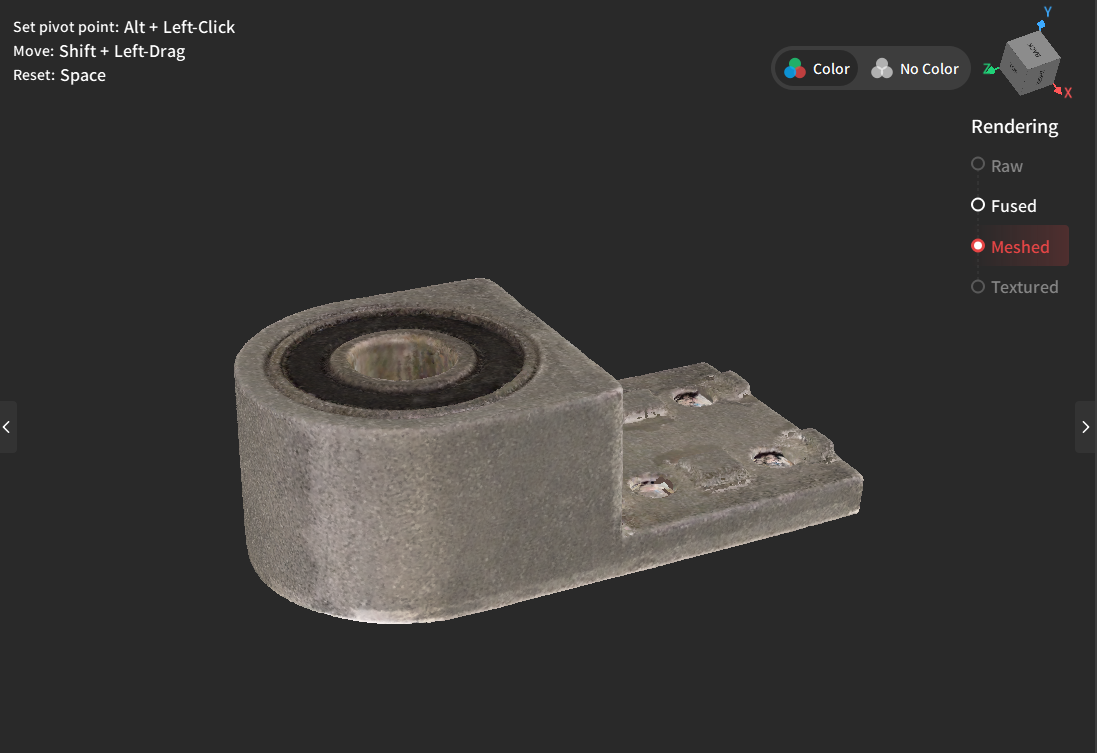

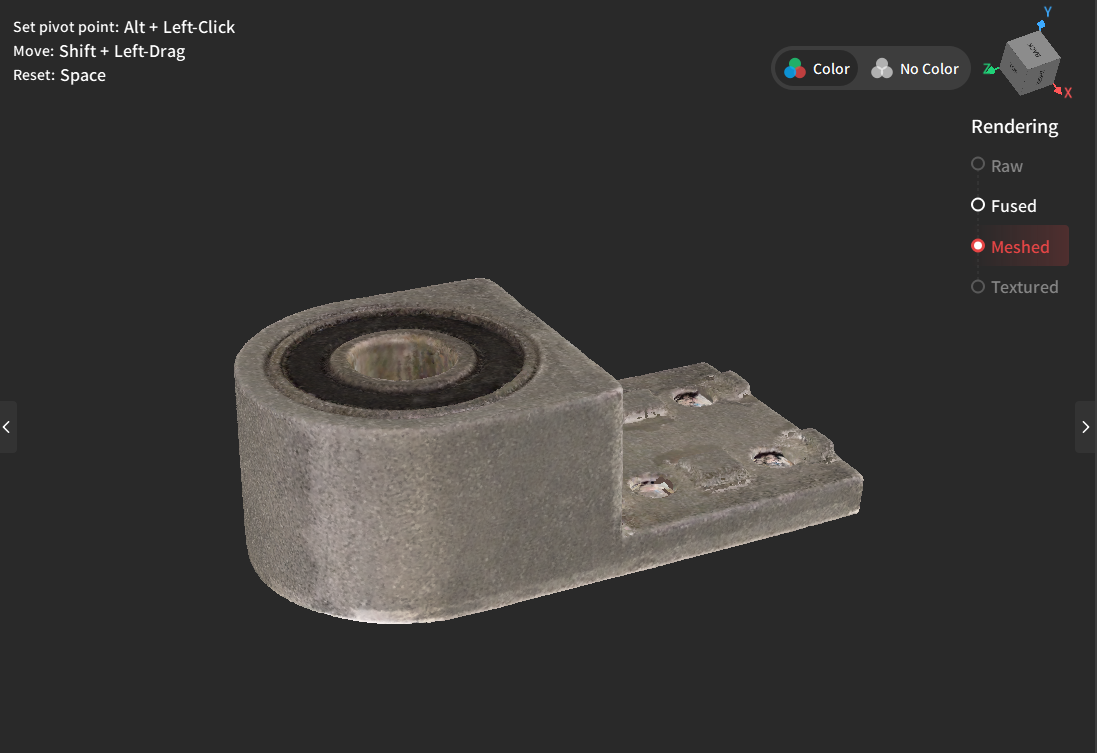

Marker Scan (Auto Turntable mode – coloration) Bearing Housing

For the subsequent scanning check, we wished to strive one thing metallic, so opted for a bearing housing that I’m utilizing to make a treadmill for my cat.

I’ve been ready for this half to reach for some time, therefore why our overview was a bit of delayed. I really needed to scan it for correct engineering causes, so I figured I’d kill two birds with one stone, and scan it for the overview so I may use the scan knowledge in my CAD work later.

The floor end is matte aluminium, so didn’t require use of a twig.

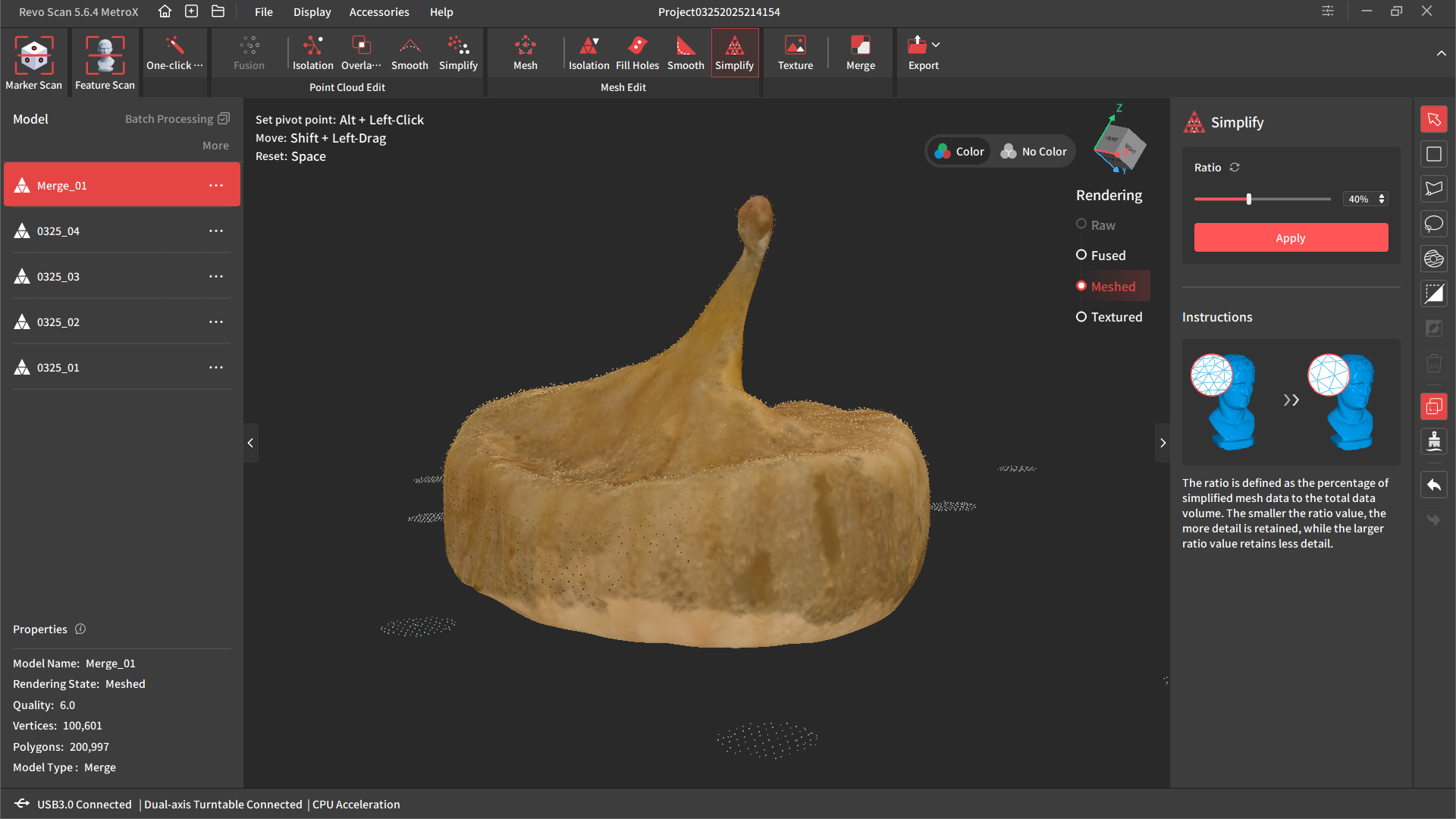

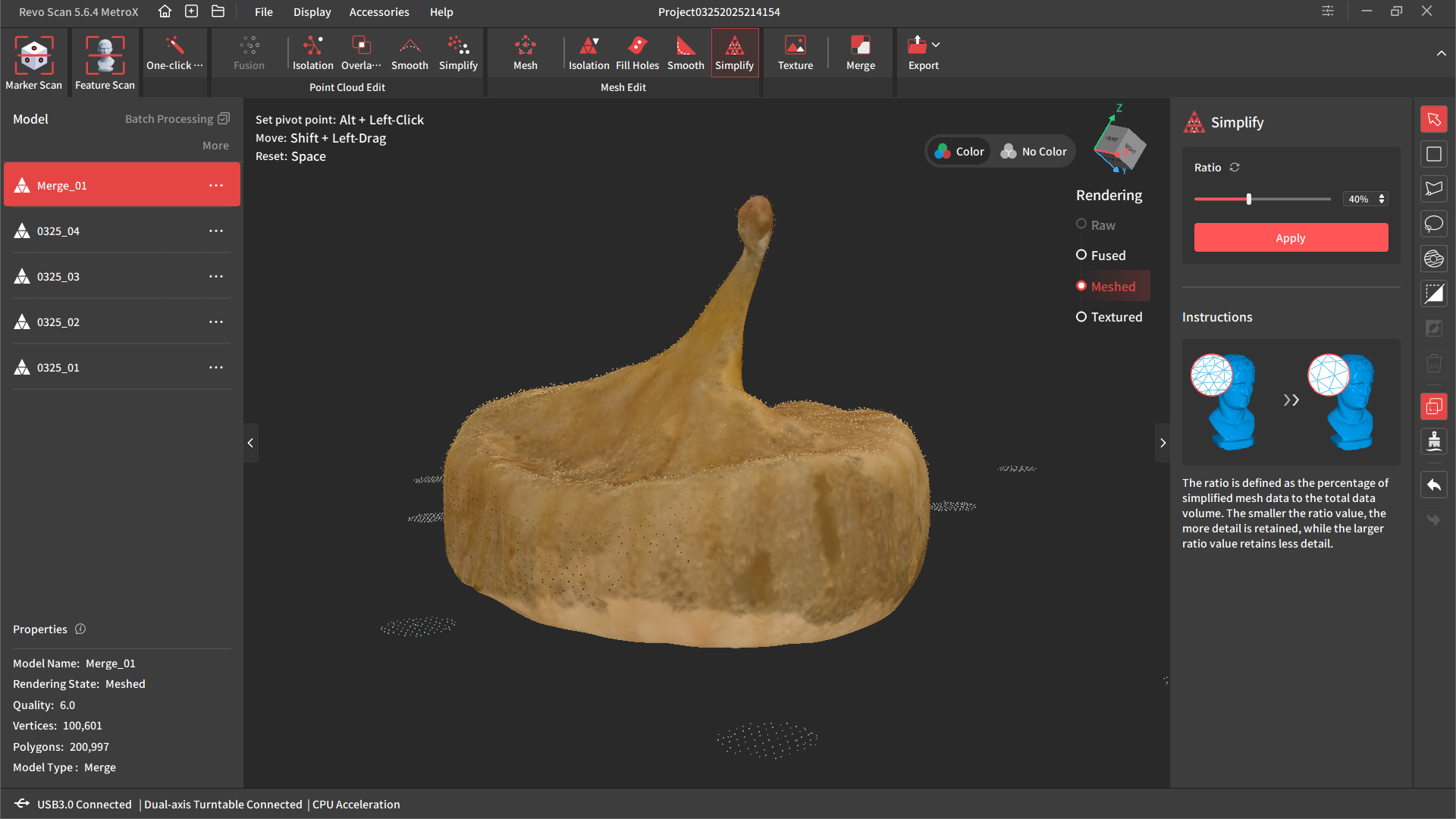

Marker Scan (Auto Turntable mode – coloration) – A Dried Fig

Subsequent for the colour scans, I scanned a dried fig. It’s not a really technical topic, however I had a field of figs mendacity round and I used to be curious what it will seem like. Once more, I used the markers on the turntable, and the piece of dried fruit scanned high quality.

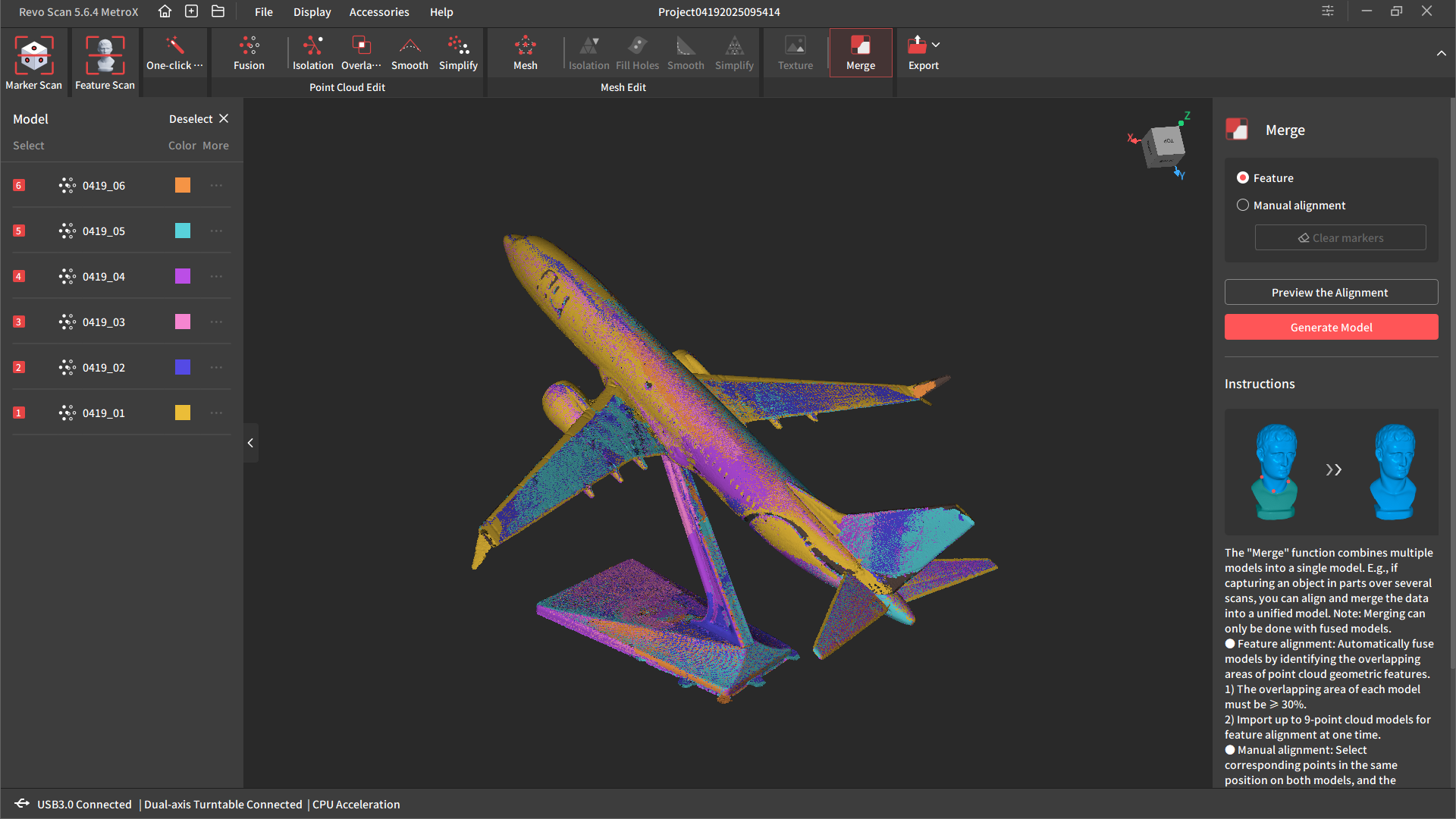

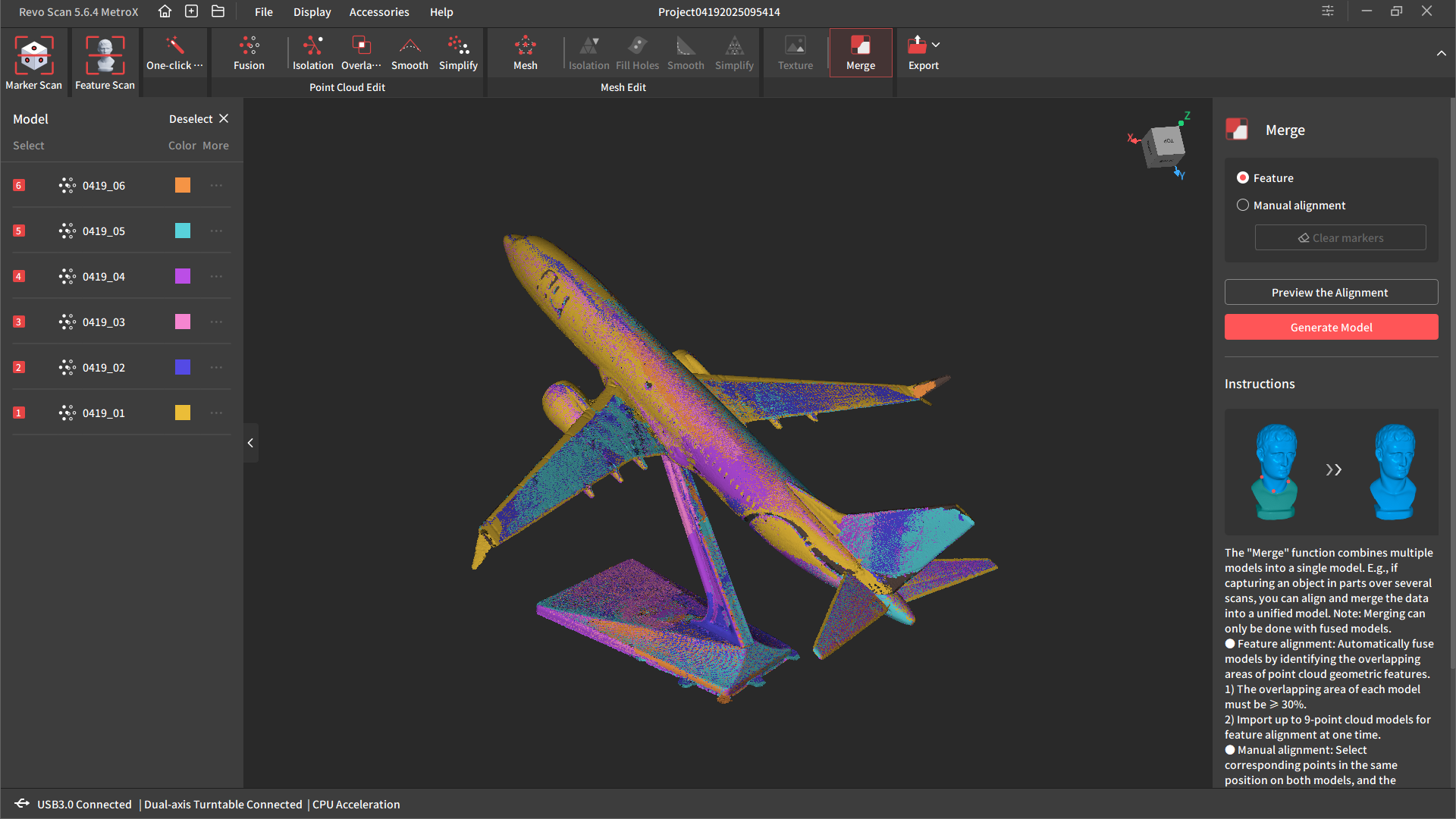

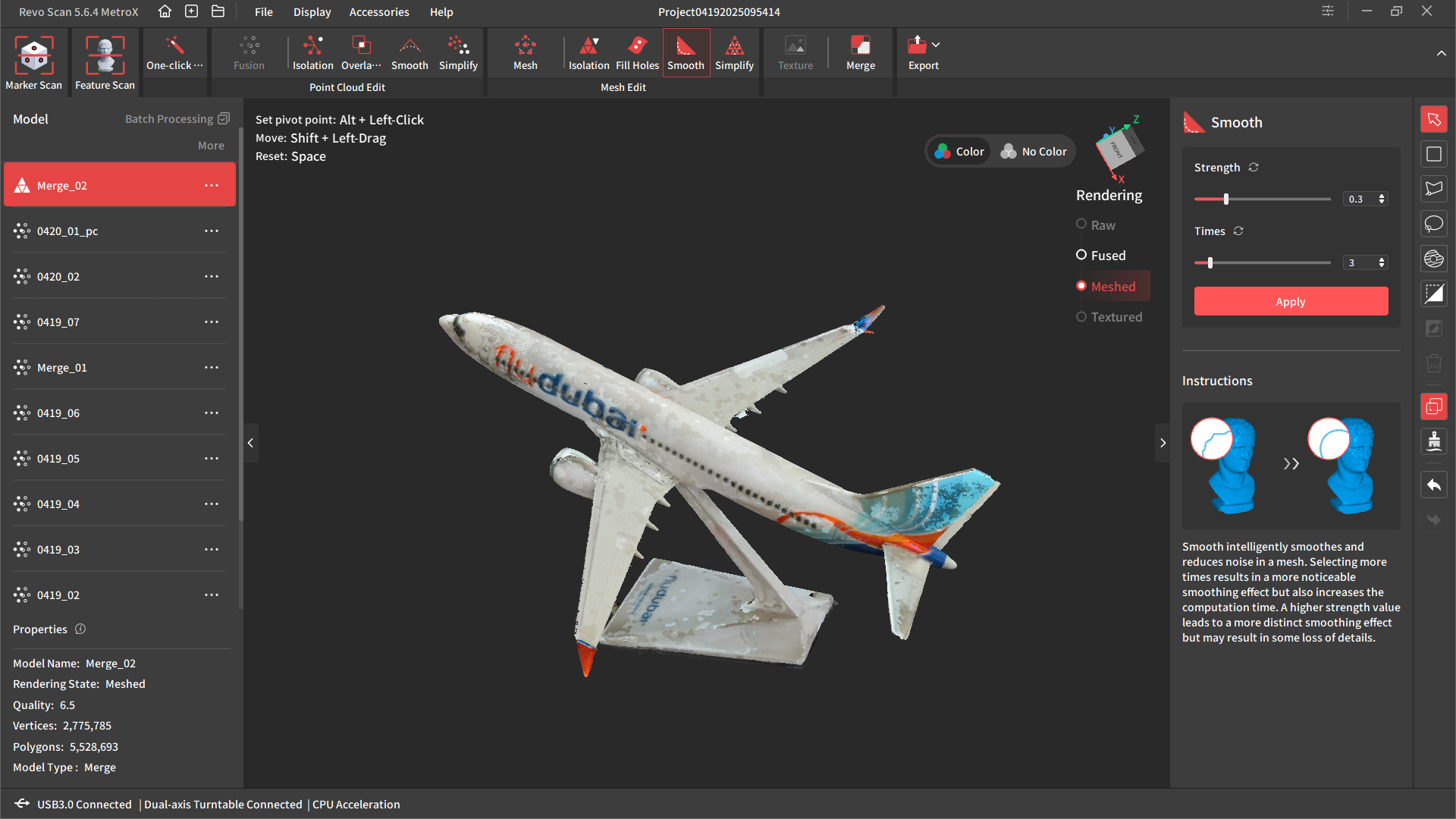

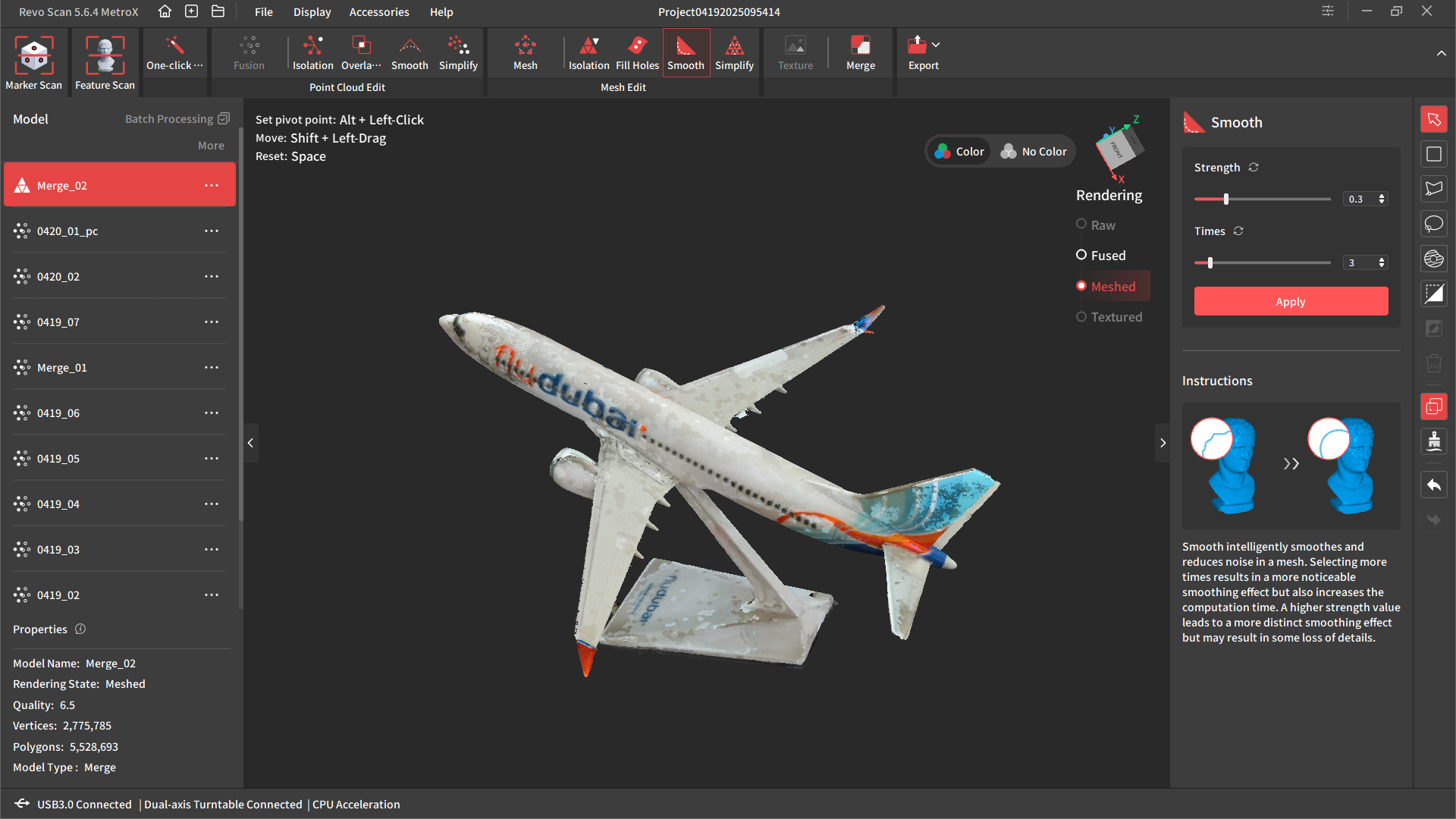

Marker Scan (Auto Turntable mode – coloration) – Plane Mannequin

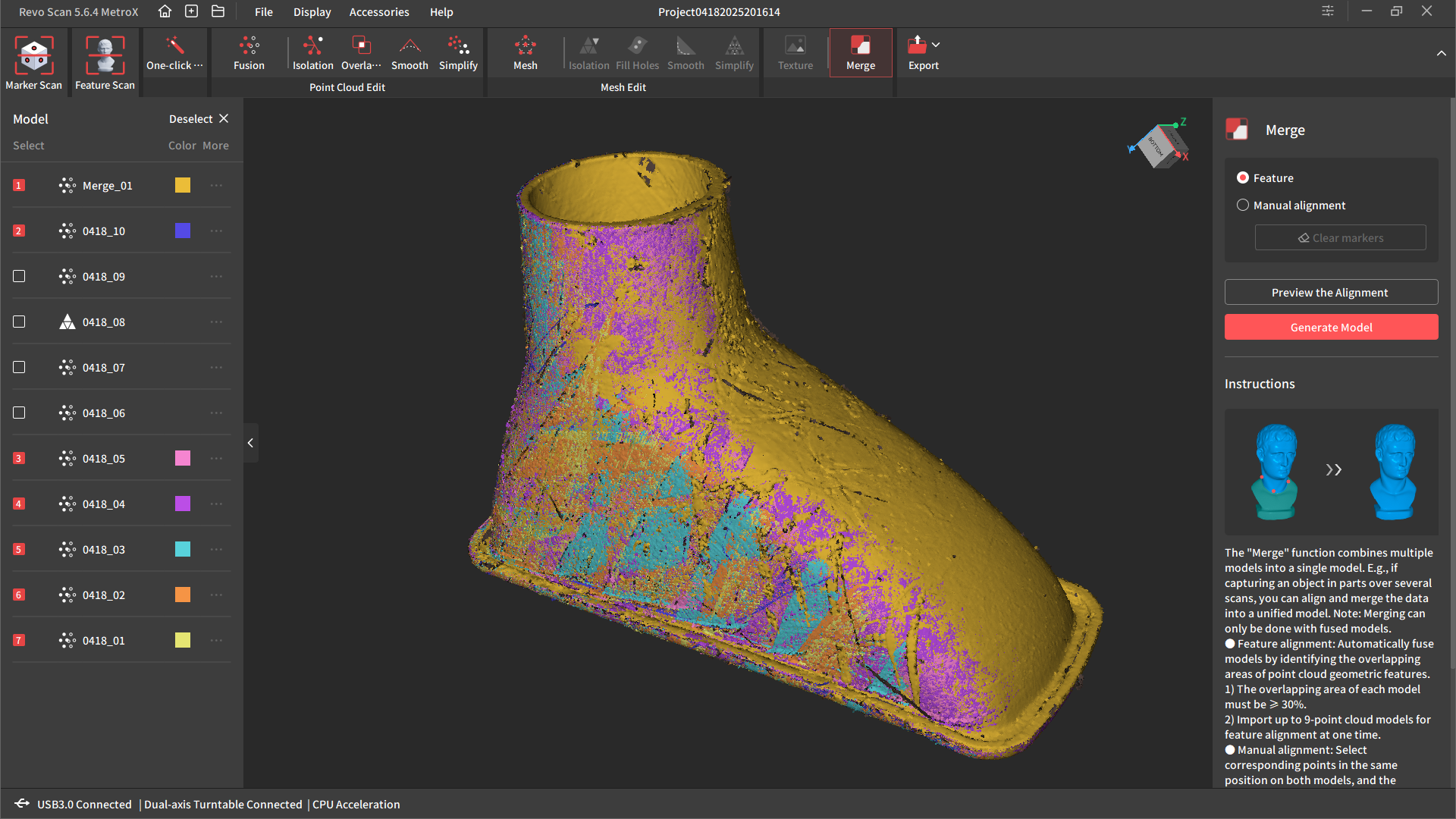

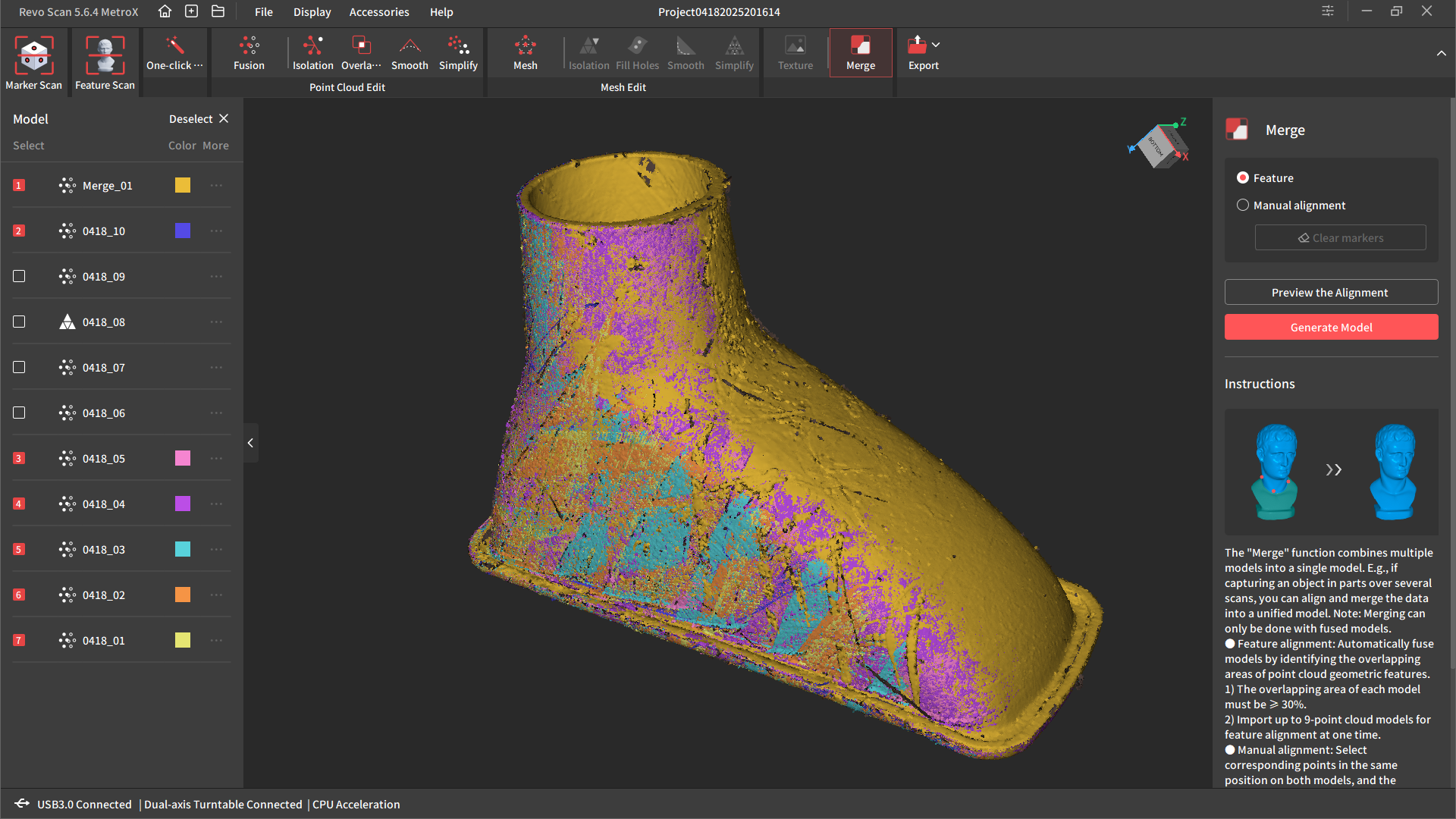

For the ultimate coloration mode check, I scanned a mannequin of an plane. This was an attention-grabbing mannequin to scan and I discovered just a few tips from the method that may not be obvious from merely studying the guide. This required a number of scans from completely different heights earlier than merging the scans within the software program. As you possibly can see within the picture beneath, the merging course of consisted of 6 completely different scans, and it turned out high quality. Bear in mind, you want a 30% overlap for merging to work.

The picture beneath exhibits the merged, meshed and textured last outcome. There may be some variation in coloration and shading of the varied scans, largely as a result of me altering peak between scans, affecting the shadows on the mannequin. For a extremely good coloration scan, it’s simpler to seize the item in a single scan from the turntable (with out shifting the scanner). Having constant lighting is vital right here.

Characteristic Scan (Auto Turntable mode – coloration) – Battery Charger

For the subsequent check, I wished to strive the Characteristic Scan mode, which permits scanning of feature-rich topics with out the usage of markers. For this, I used a drone battery charger. The charger had quite a lot of metallic, plastic and glass surfaces, in addition to a spread of darkish/gentle colours and different options.

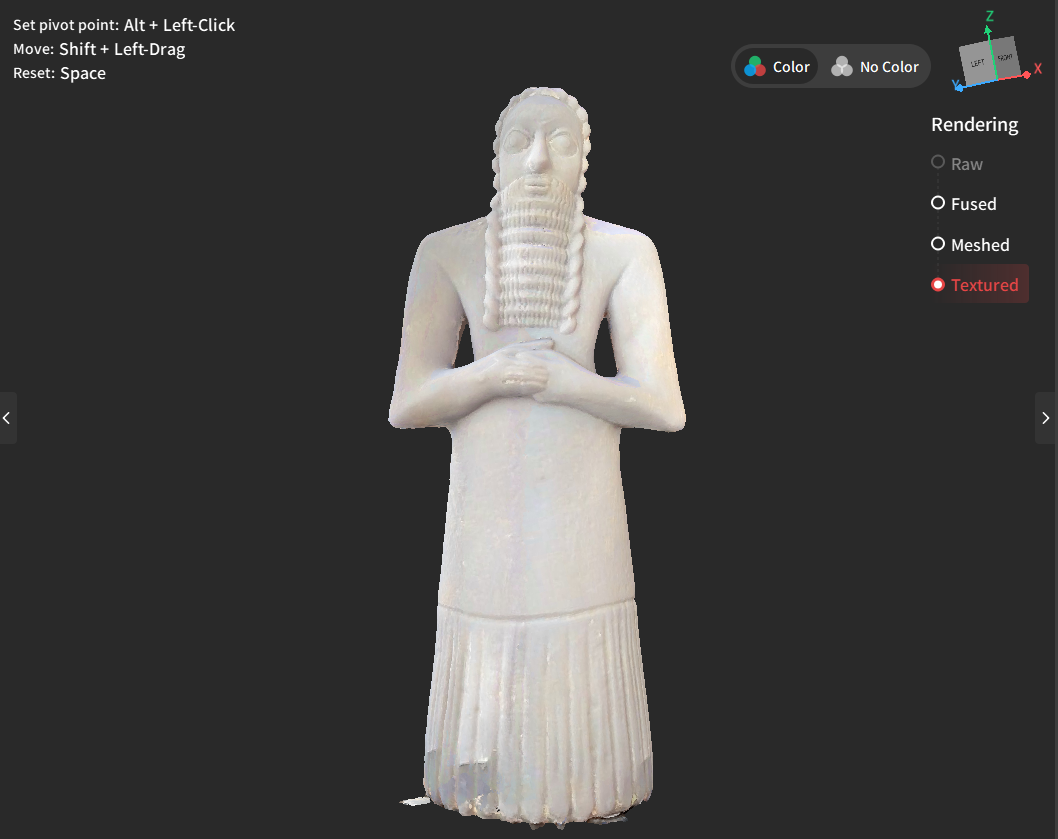

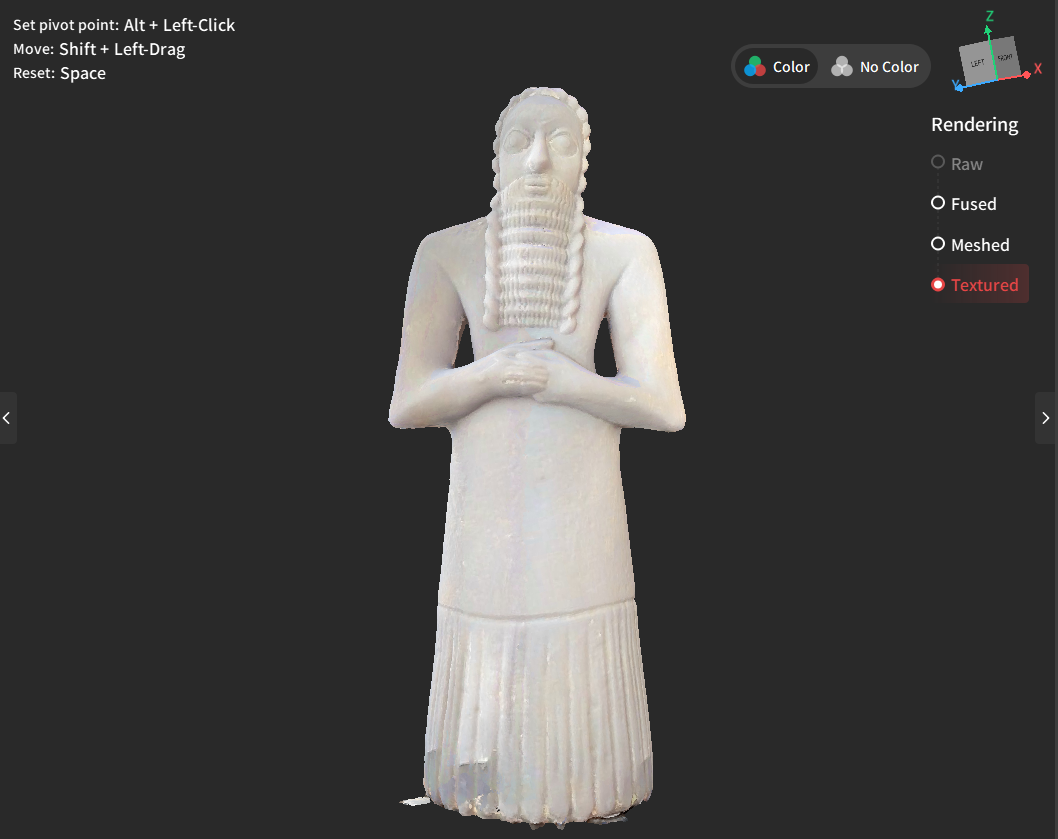

Characteristic Scan (auto turntable mode – coloration) – 3D Printed “Ea-Nasir” Statue

For my last function scan check, I used my 3D printed statue of infamous Sumnerian copper service provider “Ea-Nasir”. The scanning of this determine was lots simpler than the battery charger, because it has numerous distinct, not planar, non-repetitive geometry.

Laser Line Scanning Modes

With the 2 laser scanning modes, blue lasers emit extremely centered beams with minimal dispersion, permitting for extra correct floor profiling on sharp edges, high quality options, and small components. Not like structured gentle, which initiatives a complete sample without delay, laser scanning captures a number of traces, making it much less delicate to ambient lighting and higher suited to use on darkish, shiny, or extremely textured surfaces.

It additionally tends to penetrate deeper into floor recesses and complicated geometries. Whereas blue structured gentle scanning is quicker for full-field seize and extra compact in {hardware} design, blue laser techniques usually ship superior decision, decrease noise, and better repeatability, making them the popular alternative for industrial inspection and metrology-grade purposes.

So with the structured gentle modes properly and really put by their paces, it was time to check the laser line scanning modes (parallel traces and cross traces).

Marker Scan (laser traces) – Air Duct

The primary merchandise to scan with the laser modes was a bit of bit bizarre, as it’s a automotive consumption duct with two floor finishes. It’s designed to resemble carbon fiber, nevertheless it’s really molded that manner, with alternating shiny and matte black parts zig-zagging alongside one another.

First I attempted the auto-turntable mode for a coloration scan, and as predicted, solely the matte zig zags have been captured within the scan. Non-color full area scanning yielded the identical outcomes.

So I arrange a cross line laser scan, utilizing the turntable, and the outcomes have been a lot better. The cross traces had some problem reaching contained in the duct, so I paused the scan, and switched to a parallel line laser scan. I unpaused the scan and resumed, and the parallel traces reached just a few of the areas that might not be reached earlier than.

Whereas I used to be not capable of seize the whole inside surfaces of the duct (because of the geometry of it), I do just like the function of pausing, and switching scan varieties mid-scan. This does (in some instances) permit for reaching tough to scan components.

After I took just a few scans, I merged them right into a single level cloud, as you possibly can see beneath.

Marker Scan- Hand Scan (laser traces) – Fireplace Extinguisher

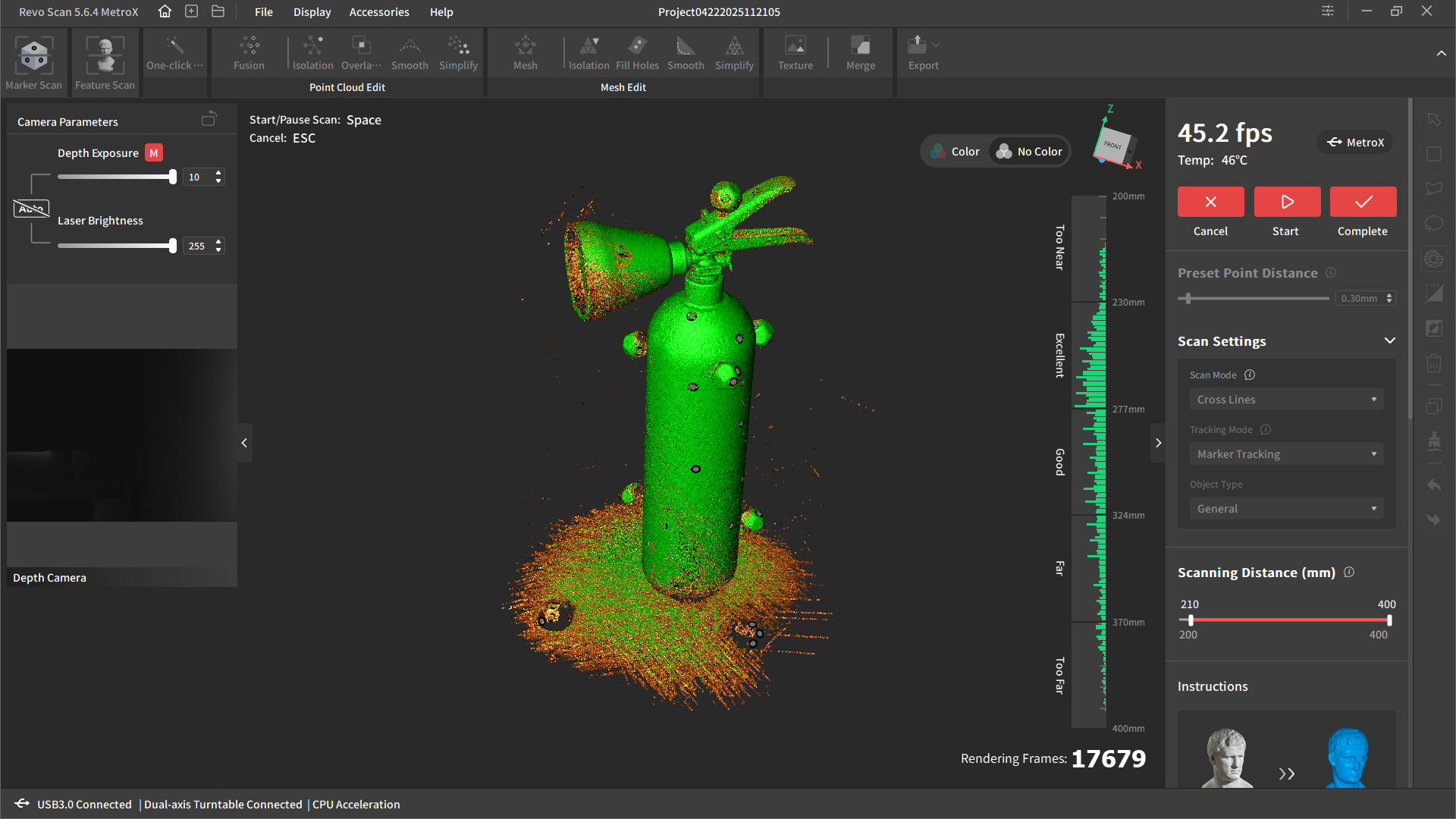

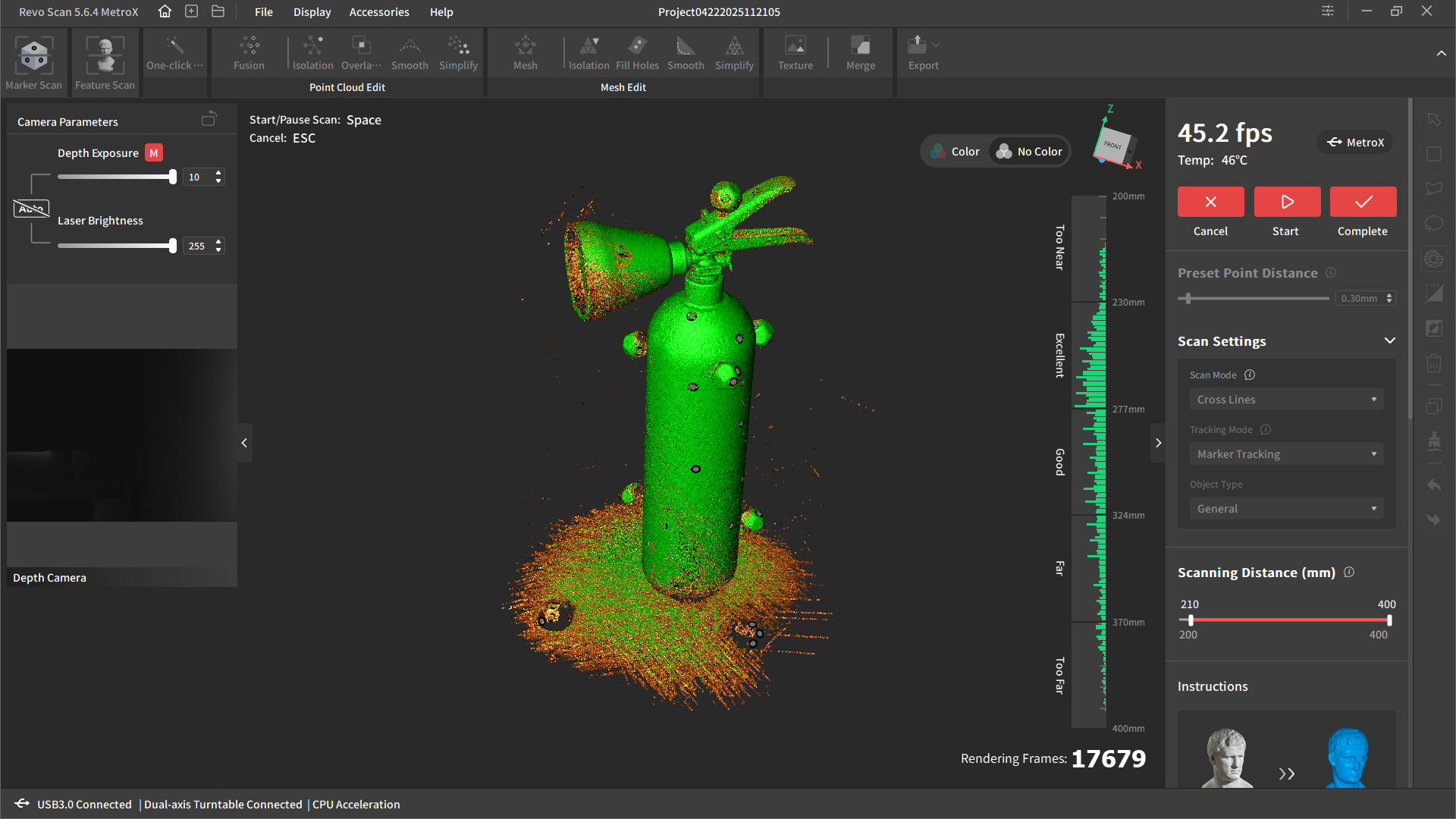

All the pieces typically works OK when utilizing the turntable (when you get used to it), so for our last check, we wished to see how the MetroX carried out on a bigger object, particularly a hearth extinguisher.

I dutifully lined the fireplace extinguisher with sticky markers, and some of the 3D plastic marker blocks, and began a cross line scan.

It labored high quality for probably the most half, and was capable of seize the entire number of surfaces and supplies, starting from the pink paint to the black plastic mesh on the nozzle.

The software program demanded that I wanted “extra markers” rather a lot, which was a bit annoying, as a result of as you possibly can see within the picture above, there have been various markers on it already. To be truthful, the fireplace extinguisher has a curved floor, and the sticky markers work higher on flatter surfaces. So even if it was lined in markers, the scanner had some points with detecting the sticky markers from extra shallow angles because the floor curved round.

The ball-shaped strong markers are higher for any such utility, nonetheless, there are solely 10 of the ball-shaped magnetic markers in our package, so this might not be sufficient to scan the extinguisher with out getting the “extra markers” error normally. So I distributed just a few of the opposite strong markers on the ground across the hearth extinguisher as properly.

For those who’re going to be scanning one thing massive and curved, you’re going to want extra magnetic markers and doubtless numerous sticky markers too. However general, as quickly because the “extra markers” error had vanished, the scan was fairly easy for this topic.

Within the software program, the graphical illustration of the item turns inexperienced in areas the place the scan has been profitable, and orange the place it wants extra scanning, as you possibly can see within the picture beneath.

General, the laser scanning modes work fairly properly, though an extended USB cable would make life a bit of simpler for hand-scanning, particularly for those who’re tethered to a desktop PC and never a laptop computer.

Abstract

As we’ve seen within the check sections, the Revopoint MetroX provides two core scanning applied sciences: blue structured gentle and blue laser line scanning, every with its personal strengths.

Structured gentle is utilized in Full Subject and Auto Turntable modes, and when paired with the built-in RGB digicam, permits correct coloration scans (although solely in Auto Turntable mode).

Laser line scanning (with parallel or cross-line patterns) excels on tough surfaces like shiny plastics or curved metallic components, and even enables you to swap laser modes mid-scan to succeed in tough areas.

All in all, each techniques work properly as soon as dialed in, however they take a little bit of observe to grasp, particularly with regards to scan merging, marker placement, and navigating geometry-specific challenges.

Suggestions for Utilizing the MetroX

The MetroX could be fairly difficult to work with, however like with most scanners, the outcomes get higher the extra you get used to utilizing it.

We’ve observed just a few issues not talked about within the guide that may assist make scanning a bit of bit simpler.

- 1) Completely cowl the pillars with markers.

The 4 threaded pillars that should be screwed onto the highest face of the turntable are meant as a floor for attaching the magnetic 3D formed markers. You would possibly discover that even with the pillars lined with the magnetic shapes, you continue to get the “Wants extra markers” error whereas scanning. The answer? Completely cowl the pillars with sticky markers, on each face. As soon as we did this, the incidence of the “Wants extra markers” error was decreased considerably.

- 2) Be Cautious When Utilizing the 3D Formed Markers Immediately on the Turntable.

The 3D markers have magnets within the backside of them. The turntable has a motor, which generates slight fields which may create a drive within the markers when they’re positioned on the rotating turntable. In consequence, the 3D markers can transfer relative to the rotating turntable. You actually don’t need this. So when utilizing the 3D markers on the turntable, both affix them to the 4 pillars, or attempt to discover a candy spot on the turntable the place they won’t be affected by the fields generated within the turntable.

- 3) Use The Pause Button for Textured Scans

As talked about, there’s a “merge” function that can be utilized to hitch separate scans of an object from completely different angles right into a coherent single mannequin. This works rather well for the blue laser modes and full area, however when merging separate coloration scans, the outcomes could be a little unpredictable. As a result of the mannequin might have been moved or rotated, the shadows can change between scans. This can lead to a patchy / bizarre texture when merged.

To keep away from this, when making coloration scans, as a substitute of constructing separate scans, make use of the “pause” button. Improve the variety of rotations on the auto turntable settings, and after every rotation, merely pause the scan, and regulate the angle / peak of the scanner. On the finish of the scan you should have a extra constant texture.

Options We Would Prefer to See in Future

Having tried the MetroX for these previous few months, we’ve acquired used to its quirks. However we predict that including these different options (presumably by way of software program replace) would enhance the person expertise fairly a bit.

- 1) Extra accessible turntable controls.

When utilizing the turntable, you both need to navigate into turntable settings, or bodily push the buttons on the turntable to tilt. And you can not simply change path of the turntable mid-scan.

This might simply be resolved by including fundamental turntable controls for tilt angle, velocity, and path on the primary display in Revoscan.

- 2) Depth Digicam Setting Reminiscence

When doing a turntable or full area scan, the depth digicam settings are reset to the default setting after every scan. That is extremely annoying, and contributes to the patchy textures talked about within the earlier part. The RGB digicam settings keep mounted on the user-defined values between scans, so why does the depth digicam setting return to default when beginning a brand new scan?

- 3) Inspection Options

This can be a huge one. The MetroX is marketed as an expert metrology-grade scanner. It could be actually nice if we may do precise metrology-stuff (like measuring the gap between factors or on the mesh) inside Revoscan.

The present answer, if you wish to measure something, is to make use of third get together software program, like Zeiss Examine (previously Gom Examine), or Geomagic Management. This shouldn’t be too tough to implement, and would actually make life lots simpler.

- 4) Shade Scanning Outdoors of Auto-Turntable Mode

At the moment, you possibly can solely do coloration scans in auto-turntable mode. It could be good to have the ability to do coloration scans with out the turntable. We are able to do it with the Revopoint Miraco, so it’s a bit of odd that we can’t do it with the MetroX.

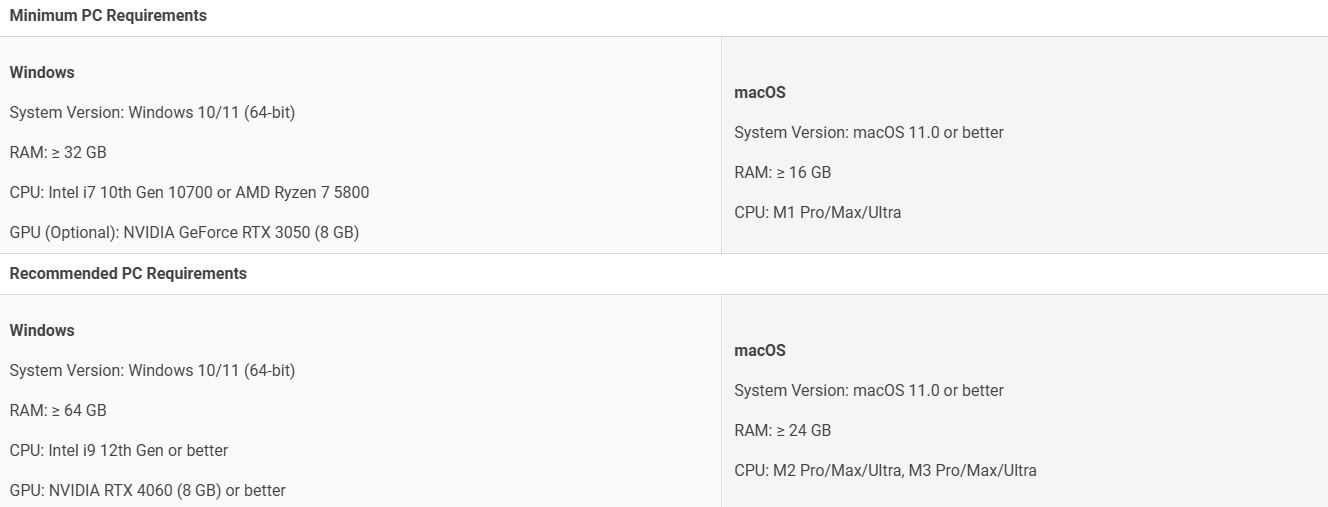

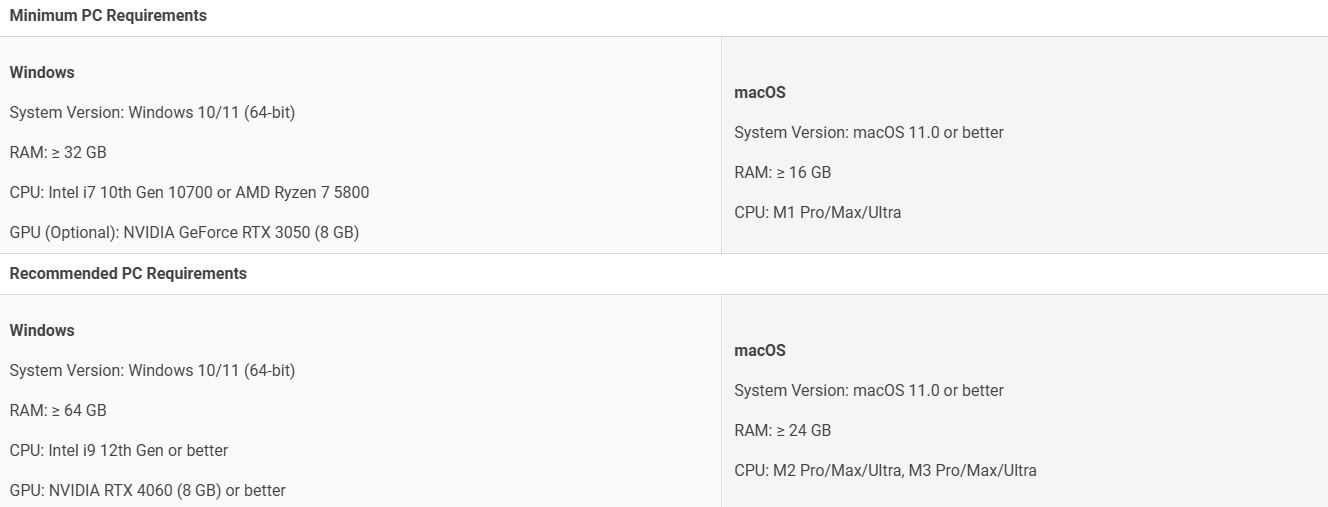

Minimal PC Necessities for MetroX

We should always take a second to deal with one thing that has been a priority of potential prospects on-line – the PC {hardware} necessities for utilizing the MetroX. You’ll be able to see the minimal and advisable system necessities within the desk beneath.

As you possibly can see, the minimal necessities name for an Intel Core i7 tenth era or higher, with 32GB of RAM and an non-compulsory GPU, minimal RTX3050.

The advisable necessities are an Intel Core i9 (tenth gen onwards) with 64GB RAM and an RTX 4060 or higher.

Some commenters on-line have been involved that they could need to rush out and improve their CPU, RAM, GPU, and even their energy provide unit simply to run the MetroX.

This may not be mandatory when it comes to the minimal necessities.

For our check, we had 64GB of RAM, no devoted GPU, and we used an Intel Core i5 thirteenth era (13400), which has 10 cores (6P + 4E) and 16 threads, versus 8 cores and 16 threads for the tenth gen i7.

The Core i5 additionally has a more recent structure (Raptor Lake) in comparison with the older i7, so it’s higher in effectivity, higher energy/efficiency ratio, and higher at multitasking. The common (non-Ok model) of the tenth gen i7 has a barely increased base clock velocity than the i5, however in all different regards, the i5 thirteenth gen is the superior CPU when in comparison with the tenth gen i7.

What does this imply?

It signifies that in case you have an i5 thirteenth gen or newer, you already meet (or exceed) the minimal necessities when it comes to CPU. So that you don’t have to rush out and purchase an older i7 in case you have a newer i5.

Our setup labored high quality for turntable scans in all modes. Our largest concern was that it would have an effect on the scanning of bigger objects when doing hand scans, nevertheless it was principally high quality. There was a bit of stuttering when doing the fireplace extinguisher by hand, particularly when the full variety of frames elevated considerably.

So our advice is to purpose for a bit of increased than the minimal necessities. A thirteenth gen i5 with 64 GB of RAM and an RTX 3060 (or increased) needs to be OK.

Clearly in case you have the advisable necessities of an i9 and every little thing else that Revopoint lists within the desk, then you should have a noticeably smoother expertise.

The purpose is, you may not want to purchase a brand new CPU in your desktop machine.

Now, for those who’re working a laptop computer setup, then this can be a completely different story. It’s not straightforward to improve a laptop computer CPU / GPU.

For those who personal a laptop computer and it doesn’t meet their minimal necessities (or our personal advisable minimal necessities), then you definitely’re out of luck and also you’re gonna want a brand new laptop computer. So bear that in thoughts when making a purchase order.

Conclusion: Why MetroX Is a Stable Entry-Degree Metrology Possibility

There’s a transparent area of interest that the MetroX fills, and that may be a sub-$1,000 scanner that flirts with the sting {of professional} metrology efficiency. For those who’re in product improvement, small-scale manufacturing, or want dimensional inspection on a price range, this scanner deserves critical consideration.

For context: metrology-grade scanners from manufacturers like Creaform, GOM, or Hexagon typically begin at $20,000 and go properly past $100,000, relying on accuracy, software program suite, and certification. These techniques provide traceable calibration, built-in inspection software program, and are nice for ISO-certified workflows, however the worth and studying curve are steep.

MetroX isn’t making an attempt to interchange these techniques. What it does provide is one thing shut sufficient for a large swathe of customers who want exact, repeatable 3D knowledge (however who don’t want NIST traceability or enterprise-level overhead).

The flexibility to scan sure shiny components with out spray, handle multi-angle full scans by way of markers, and get a secure mesh output all for beneath $1K is large. The principle limitations are in software program. RevoScan MetroX lacks built-in inspection instruments (for now), which means dimensional checks should be carried out in third-party software program, as talked about beforehand.

However hardware-wise? MetroX punches properly above its weight. If Revopoint provides even a fundamental measurement toolkit to the native software program, MetroX may grow to be a go-to scanner for small labs, universities, fabrication retailers, and even restore & reverse engineering groups that don’t have tens of hundreds to spend.

For extra info on the Revopoint MetroX, you possibly can click on our affiliate hyperlink beneath, or head on over to their product web page right here. Don’t overlook to make use of the low cost code “RE3DPT” when buying for an additional saving.

RevoPoint MetroX

The RevoPoint MetroX combines blue-laser traces and full-field scanning, enabling scanning of a large number of various surfaces by way of its completely different scanning modes.

- – Accuracy: As much as 0.03 mm

- – Body fee: As much as 60fps

- – Work distance: 200 ~ 400 mm

- – Single seize vary: 160 x 70 mm at 200 mm and

320 x 215 mm at 400 mm - – Dimensions: 209 x 88 x 44 mm

- – Seize objects with 7 high-powered parallel blue laser traces

- – No spray wanted to scan shiny or black surfaces

- – Marker blocks assist scan sooner

For those who’ve loved studying in regards to the MetroX, keep watch over Revopoint’s subsequent launch: the Trackit 3D Monitoring Scanner will probably be obtainable quickly on Kickstarter. As we speak they’ve opened Tremendous Early Chook pricing; safe your 35 p.c low cost and VIP perks by signing up right here.