On this article, we evaluate the Centauri Carbon, Elegoo’s first totally enclosed, CoreXY FDM 3D printer.

The Shenzhen-based 3D printer producer’s newest desktop FDM providing was revealed throughout RAPID + TCT 2024 and made commercially out there in February 2025. It provides to the corporate’s open-architecture Neptune and OrangeStorm Giga lineup whereas complementing Elegoo’s reasonably priced resin 3D printer vary.

With costs beginning at simply $299.99, Elegoo’s Centauri Carbon has already captured consideration within the desktop 3D printing market. Providing print speeds of as much as 500 mm/s, automated mattress leveling, and broad materials compatibility, it delivers spectacular efficiency at a budget-friendly value.

The Centauri Carbon is optimized for 3D printing straight out of the field, making it very best for newcomers and hobbyists. Moreover, its enclosed construct chamber is designed to ensure thermal stability when processing temperature-sensitive filaments. This makes the system well-suited for extra seasoned makers trying to upscale materials properties and half high quality with out breaking the financial institution.

We put the Elegoo Centauri Carbon via 180 hours of benchmarking and utility assessments, assessing how this reasonably priced system competes within the contested desktop 3D printer market.

The Elegoo Centauri Carbon is on the market to pre-order from the official Elegoo retailer.

Why select the Elegoo Centauri Carbon?

The Centauri Carbon’s CoreXY structure leverages two stepper motors positioned on the high corners of the machine for straightforward entry. These management the print head’s actions within the X and Y axes, unlocking sooner 3D printing than Cartesian and Delta techniques.

Elegoo’s Centauri Carbon boasts a formidable 500mm/s most 3D printing velocity and 20,000 mm/s² acceleration. The system’s die-cast aluminium chassis helps to keep up strong structural integrity and decrease vibrations throughout quick print head motion. In keeping with Elegoo, this design means accuracy and high quality aren’t sacrificed in high-speed 3D printing. We put this declare to the take a look at later within the evaluate.

Excessive-speed 3D printing can be enabled by Centauri Carbon’s direct-drive print head, geared up with a dual-gear hardened metal extruder. This ensures constant and secure extrusion at a move charge as much as 32 mm/s², essential for high-speed manufacturing. Elegoo’s latest FDM system contains a 5020 high-speed, four-wire cooling fan on the rear of the toolhead. This directs airflow to the extruded materials, bettering print high quality at excessive speeds.

The Elegoo Centauri Carbon’s extruder meeting. Pictures by 3D Printing Trade.

The Centauri Carbon additionally stands out due to its enclosed 256 mm x 256 mm x 256 mm construct surroundings. Whereas it lacks energetic chamber heating, the Centauri Carbon constantly reaches round 45°C throughout prints with excessive mattress and nozzle temperatures. In flip, 3D printing high quality and materials properties are improved due to enhanced layer adhesion and diminished warping, which is brought on when extruded materials cools too shortly.

Its highly effective 1000W AC-heated print mattress reaches temperatures as much as 110°C, whereas the hardened metal nozzle, paired with a 60W ceramic heater, shortly heats to 320°C. This high-temperature functionality helps a variety of filaments, from commonplace supplies like PLA, PETG, ASA, ABS, PA, PC, and TPU to superior composites bolstered with carbon fiber, glass fiber, and Kevlar. An activated carbon filter is included with the enclosed construct chamber. This makes use of a nano-mineral crystal filter to soak up dangerous particles produced throughout 3D printing.

The Centauri Carbon’s double-sided, versatile magnetic construct plate is designed to optimize materials adhesion. Aspect A presents a textured PEI floor to help wide-ranging supplies, whereas Aspect B contains a clean floor designed particularly for PLA 3D printing. Though each can be utilized for PLA, Aspect B gives superior adhesion, requiring solely 30°C to safe 3D printed elements. This decrease temperature reduces power utilization and minimizes warping.

The Elegoo Centauri Carbon’s print mattress, spool holder, and body. Pictures by 3D Printing Trade.

Newbie-friendly 3D printing with minimal setup

Elegoo’s newest FDM 3D printer comes totally assembled and able to print proper out of the field. With assist from the included handbook, we had the system up and working in beneath 20 minutes. Even customers with minimal expertise ought to discover the setup fast and simple.

For these new to 3D printing, calibration generally is a daunting and time-consuming job. Elegoo’s Centauri Carbon addresses this with totally automated mattress leveling. Utilizing 4 stress sensors and a proprietary algorithm, the method is accomplished with a single button press.

The Centauri Carbon additionally routinely performs Z-axis compensation earlier than every print, minimizing defects attributable to uneven construct surfaces. Constructed-in vibration compensation and stress advance know-how additional improve print high quality by bettering layer smoothness and decreasing widespread high-speed 3D printing defects like ringing and ghosting.

Unboxing the Elegoo Centauri Carbon. Pictures by 3D Printing Trade.

Accessibility is additional optimized by the 3D printer’s 4.3-inch full-color touchscreen person interface (UI), which helps English, French, German, Russian, Italian, Spanish, Japanese, and Chinese language languages. This intuitive, easy-to-navigate UI is designed for all expertise ranges, providing clear management of calibration, filament loading, community connectivity, upkeep, and starting 3D print jobs.

Distant 3D print monitoring has turn out to be a key requirement for makers and industrial producers alike. The Centauri Carbon addresses this demand with a built-in print chamber digital camera, permitting customers to watch manufacturing from wherever and produce time-lapses of their print job. Nevertheless, the digital camera doesn’t present sensor suggestions as a failure prevention methodology, with Elegoo but to include micro-lidar or infrared sensors into its FDM choices.

The Elegoo Centauri Carbon’s person interface and construct chamber digital camera. Pictures by 3D Printing Trade.

Arms-on with Elegoo’s FDM slicing software program

Whereas the Elegoo Centauri Carbon is suitable with each Orca and Cura slicers, it’s optimized for the corporate’s Elegoo Slicer. This software program presents an intuitive interface with preset configurations for the corporate’s FDM printers.

Upon launching the software program, customers are greeted with a construct plate structure and quick access to printer presets, materials choices, and slicer settings. The person interface options 4 important tabs on the high: Put together, Preview, Gadget, and Undertaking. Customers can modify printer settings, orient fashions, manipulate geometry, and generate helps within the Put together tab. In our expertise, the printer presets are well-tuned and ship dependable, high-quality outcomes.

Within the Preview tab, the person can generate the G-code and think about analytical photos of the 3D printer’s toolpath. Completely different colours distinguish between options of the print, together with infill, high surfaces, outer perimeters, and different structural parts. The Preview part additionally estimates 3D print time and materials consumption.

The Gadget tab permits customers to entry distant connectivity between the Centauri Carbon and the Elegoo Slicer. Customers can monitor 3D prints by way of a stay digital camera feed. This tab additionally gives entry to print job historical past and permits on-the-fly changes to key parameters corresponding to mattress temperature, nozzle temperature, and fan velocity throughout printing.

Setting the right parameters is essential for reaching a profitable 3D print. To help with this, the Elegoo Slicer gives stay warnings, corresponding to notifying customers when helps are required however not enabled or highlighting potential stability points.

Total, we had a optimistic expertise with Elegoo’s slicing software program. It presents a simple, user-friendly platform for making ready and monitoring 3D printing. Nevertheless, it lacks a print queue function, that means customers should slice and export recordsdata individually earlier than every print job.

The Elegoo Slicer: Put together, Preview, and Undertaking tabs. Pictures by 3D Printing Trade.

Benchmarking the Elegoo Centauri Carbon

We performed a number of benchmarking assessments to evaluate whether or not the Centauri Carbon stacks up in opposition to Elegoo’s claims. The primary was a 3D printed Eiffel Tower take a look at file that got here pre-loaded with the USB stick offered. This mannequin, 3D printed in PLA, got here out very nicely, with spectacular geometries, steep overhangs, and skinny partitions. This early success confirmed that the Centauri Carbon’s materials and printer settings are nicely calibrated out of the field.

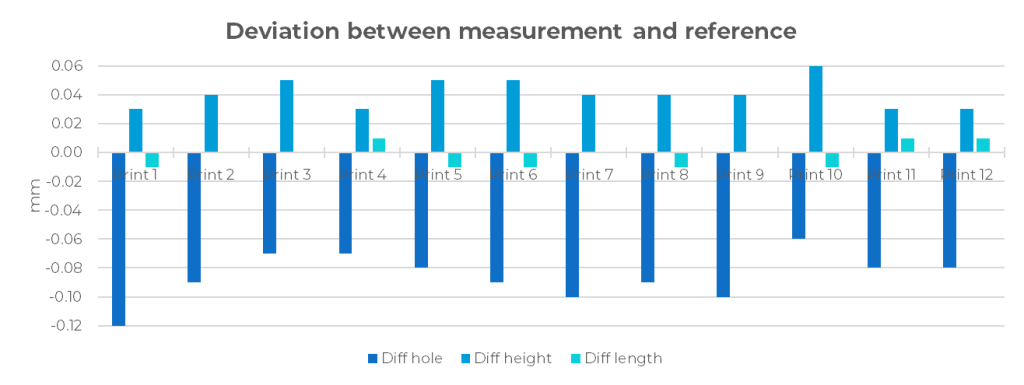

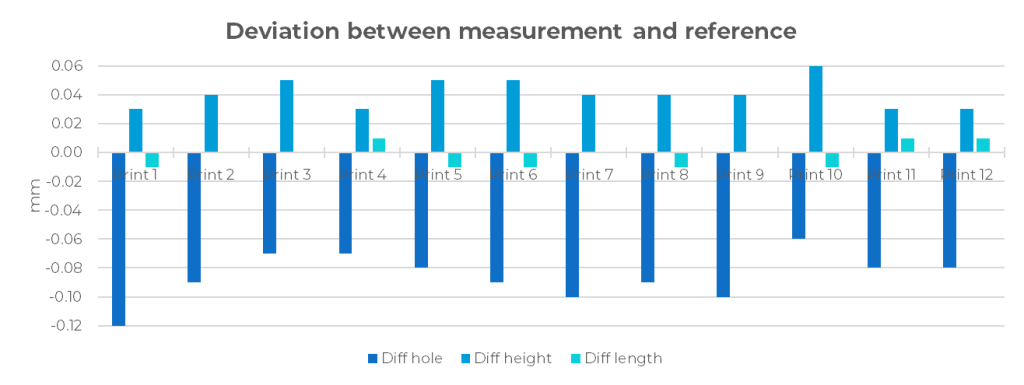

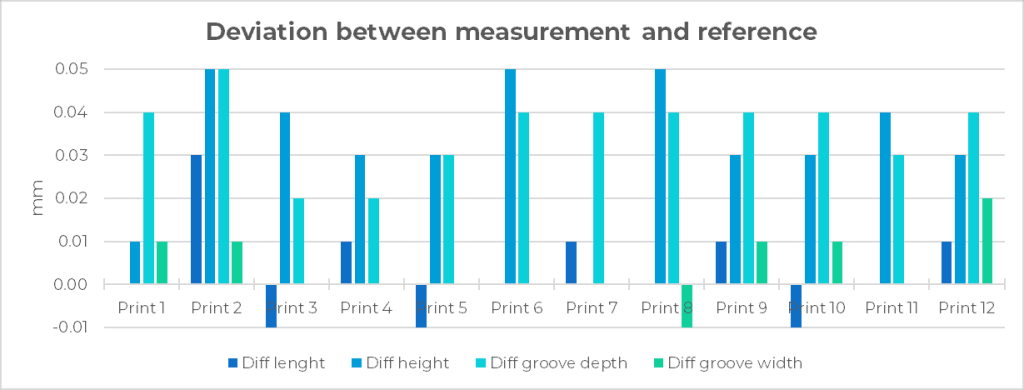

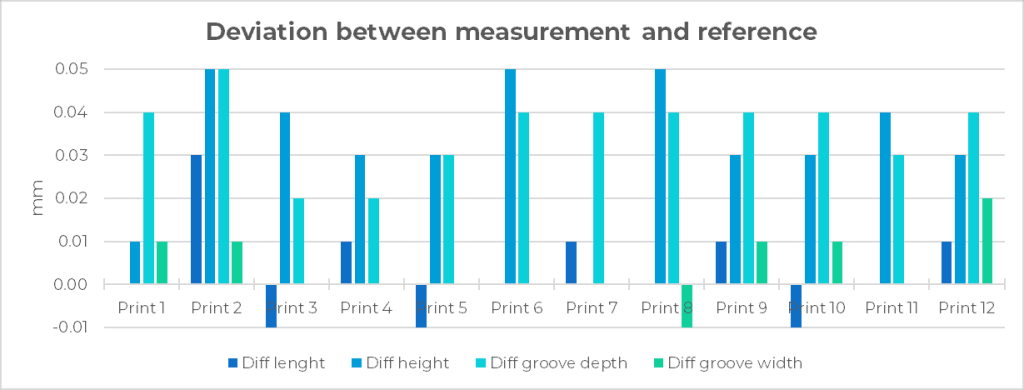

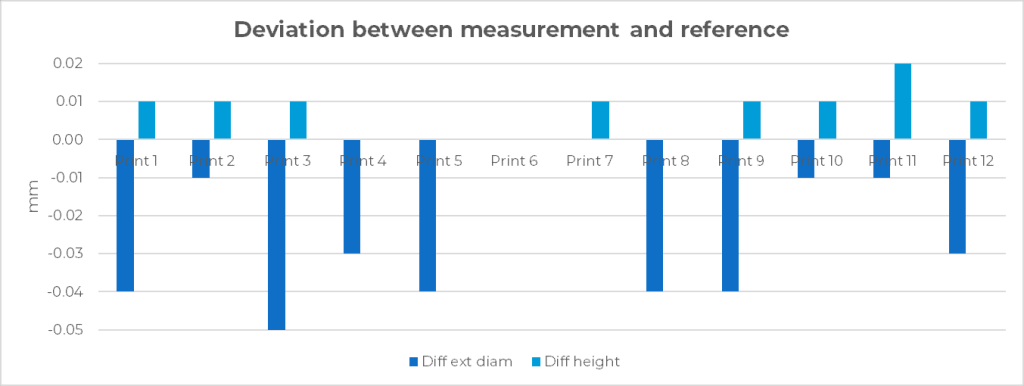

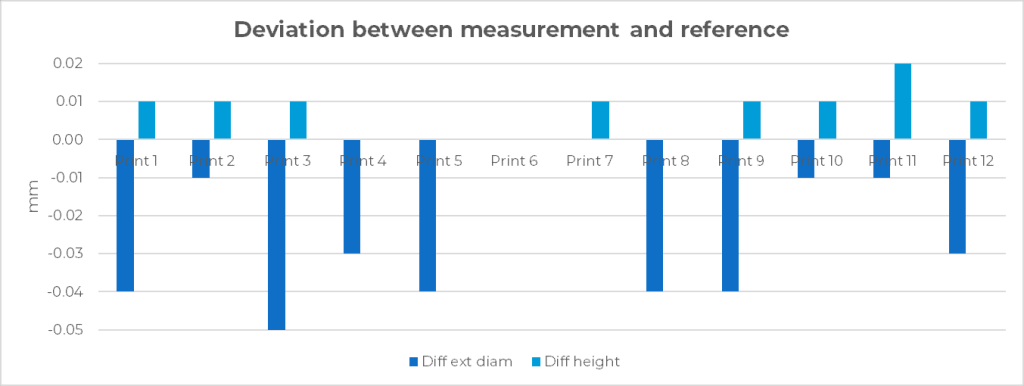

Repeatability is important when 3D printing batches of similar elements. To check the Centauri Carbon’s repeatability, we 3D printed sq., hexagon, and tube fashions 12 instances every. Our engineering staff then measured and in contrast the fashions in opposition to the goal dimensions. Succesful 3D printers are anticipated to attain a mean deviation beneath 0.1 mm and a regular deviation beneath 0.05 mm.

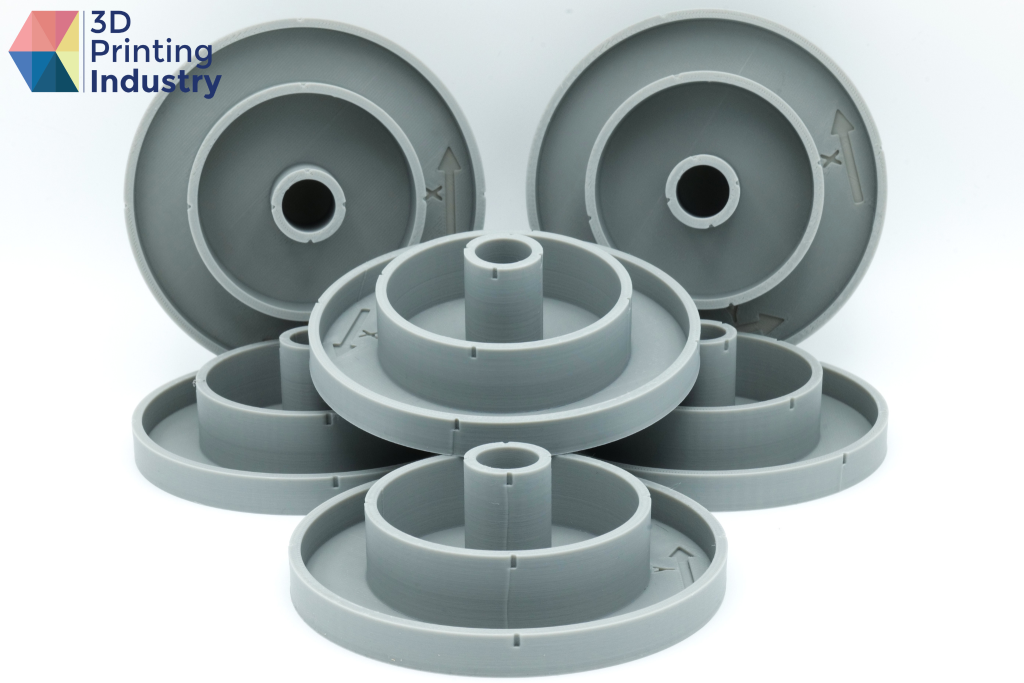

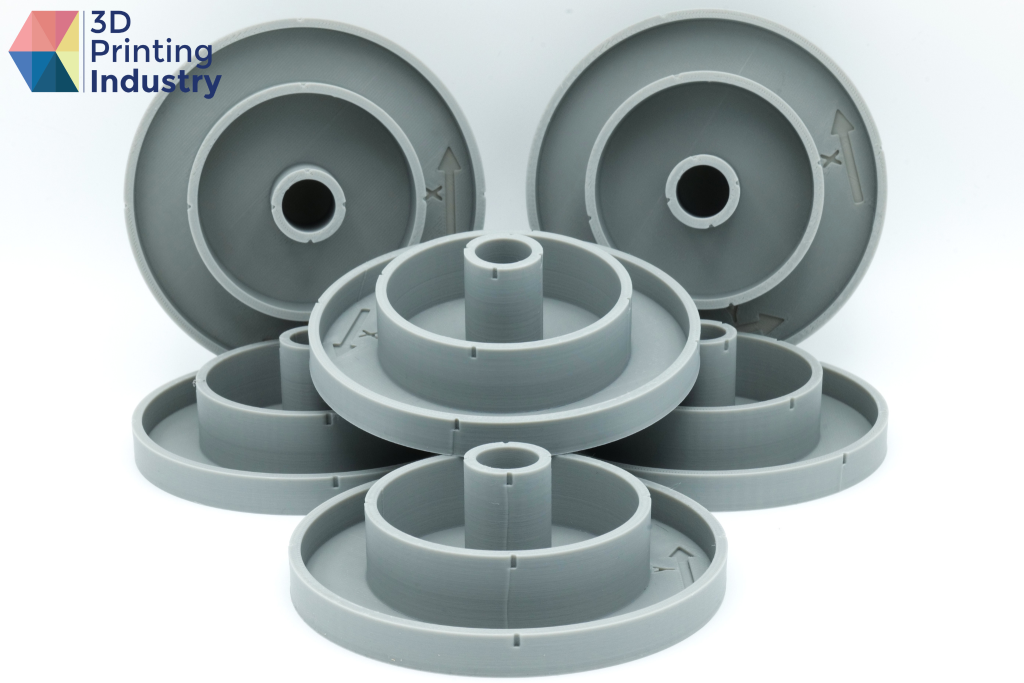

Sq., hexagon, and tube repeatability take a look at prints. Pictures by 3D Printing Trade.

Outcomes from all three fashions have been nicely throughout the benchmark figures, demonstrating spectacular precision. The sq. mannequin achieved a mean deviation of 0.0444 mm, nicely throughout the 0.1 mm benchmark, and the usual deviation was 0.0115 mm, beneath the 0.05 mm threshold.

Whereas these outcomes exhibit robust repeatability for the squares, we noticed some deviation within the gap’s interior diameter, with a regular deviation of 0.086 mm (approaching the 0.1 mm tolerance threshold). This variance was attributable to over-extrusion, a standard challenge for FDM printers, particularly when fabricating round options. Though not very best, it may be mitigated by adjusting the outlet contour compensation setting in Elegoo Slicer by +0.08 mm.

Our hexagon outcomes have been additionally robust. The typical deviation was 0.0206 mm, whereas the usual deviation was 0.0109 mm. The elements exhibited wonderful floor high quality and layer adhesion, whereas the common deviation for top was a formidable 0.0058 mm.

Notably, the hexagon corners confirmed no indicators of bulging, a standard flaw amongst FDM printers. This means that the Centauri Carbon’s stress advance know-how is well-calibrated, successfully controlling over-extrusion at sharp corners.

The typical deviation (0.0162 mm) and commonplace deviation (0.012 mm) have been nicely throughout the anticipated vary for the tube fashions. The cylinder top measurements have been notably correct and constant. Nevertheless, the exterior diameter was barely beneath the goal, ranging between 19.95 mm and 20 mm. This minor discrepancy is probably going on account of materials shrinkage fairly than extrusion points. Whereas PLA has a comparatively low shrinkage charge (round 0.3% to 0.5%), it may well nonetheless trigger refined dimensional variations.

FDM 3D printers battle with fabricating circles on account of uneven belt rigidity and G-code inaccuracies. Can Elegoo’s Centauri Carbon 3D print an ideal circle? To search out out, we 3D printed a number of fashions with round sections measuring 100 mm, 65 mm, and 20 mm in diameter, which have been in comparison with the goal dimensions. A median deviation beneath 0.1 mm for each the X and Y axes is an effective end result.

Elegoo’s FDM 3D printer handed this take a look at with flying colours, reaching an X-axis deviation of simply 0.01833 mm and a Y-axis deviation of 0.02111 mm. The imply commonplace deviation measured 0.0135 mm, nicely beneath the 0.05 mm benchmark, whereas the common deviation got here in barely greater at 0.0197 mm, nonetheless comfortably beneath the 0.1 mm threshold. These outcomes place the Centauri Carbon nicely above common for round precision in desktop FDM 3D printing.

Elegoo Centauri Carbon round trajectory outcomes. Pictures by 3D Printing Trade.

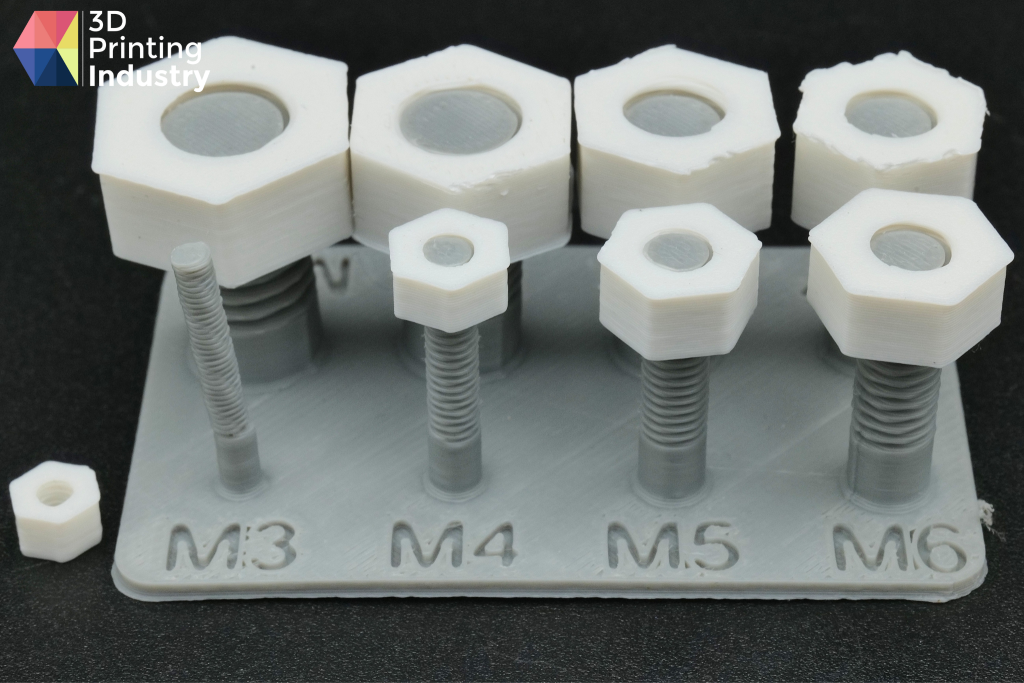

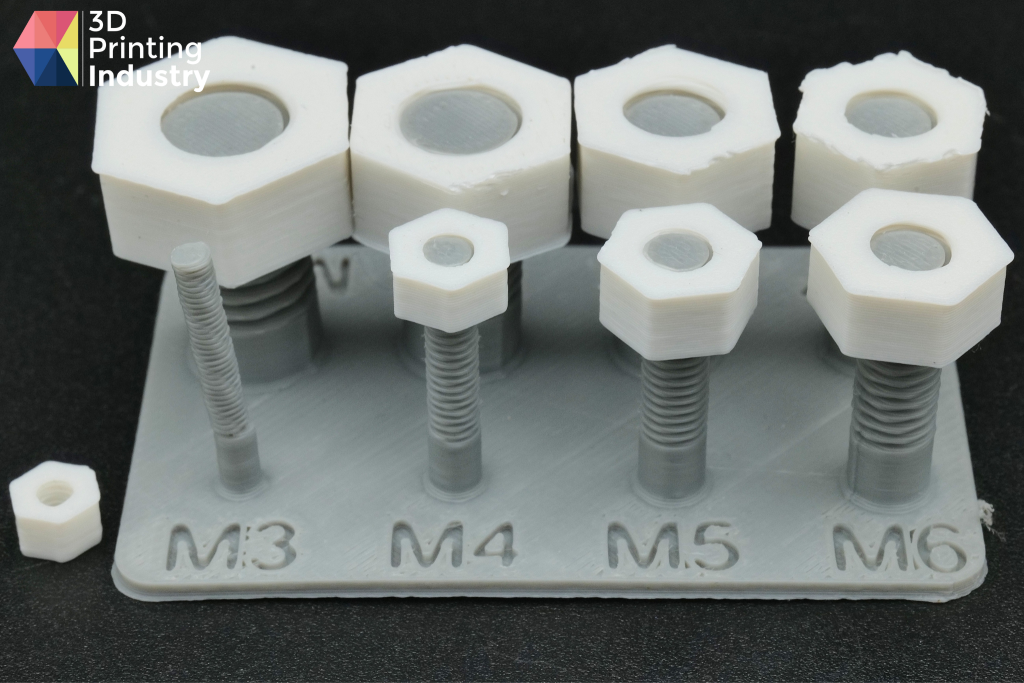

We subsequent assessed how nicely Elegoo’s Centauri Carbon handles small and exact elements with tight tolerances by 3D printing a useful nut and bolt mannequin with a 1.25 mm thread pitch and a 12 mm nut. Our staff was impressed by the accuracy of this half, which showcased wonderful element and easy performance.

We then upped the problem by 3D printing eight threads spanning an M10 1.5 mm thread pitch to an M3 0.5 mm thread pitch. The Centauri Carbon efficiently printed useful threads from M10 to M4 (1.5 mm to 0.7 mm) however failed at M3 (0.5 mm). These outcomes are spectacular and above common. Most competing FDM 3D printers usually obtain profitable outcomes solely as much as M8, reflecting the Centauri Carbon’s spectacular 3D print high quality.

For customers eager to 3D print elements with advanced geometries, overhangs and bridging sections can pose challenges. To find out whether or not the Centauri Carbon can tackle these wants, we fabricated take a look at elements with 6 overhangs every, rising by 5 levels from 40° to 65°.

Elegoo’s 3D printer produced clear, sag-free elements with no layer detachment at overhangs as much as 65°. That is spectacular, as most desktop FDM printers sometimes battle past 60°. Our assessments confirmed that cooling is more practical alongside the X-axis than the Y-axis. The primary challenge affecting the Y-axis seems to be the high-speed auxiliary fan, which cools the layers too shortly, inflicting defects at 65°.

Overhang 3D printed outcomes for X-axis (first two photos) and Y-axis (second two photos). Pictures by 3D Printing Trade.

Subsequent, we 3D printed unsupported bridge sections. The smaller bridges ranged from 5 mm to 25 mm lengthy, whereas the bigger ones spanned from 20 mm to 60 mm. The Centauri Carbon’s enclosed construct space just isn’t very best for this objective, as bridging requires speedy cooling to solidify and forestall drooping. Subsequently, when 3D printing in PLA, we advocate maintaining the door open and eradicating the highest lid. Our outcomes have been spectacular, with the 3D printer exceeding the everyday 20 mm bridge restrict amongst competing FDM techniques. The X-axis outperformed the Y-axis, reaching a superb 60 mm with minimal sagging.

3D printed bridge assessments from X-axis (first two photos) to Y-axis (second two photos). Pictures by 3D Printing Trade.

The Elegoo Centauri Carbon options 4 print velocity modes: Silent (50%), Regular (100%), Sport (124%), and Ludicrous (166%). Though the marketed high velocity is spectacular, high-speed 3D printing typically compromises half high quality. To judge the Centauri Carbon’s efficiency at completely different speeds, we 3D printed our in-house 3DPI benchmarking fashions utilizing the Silent, Balanced, and Ludicrous presets.

Silent mode accomplished the print in 6 hours and 40 minutes. Noise ranges have been noticeably diminished throughout printing, making this mode well-suited for indoor work environments. The take a look at achieved a formidable rating of 92.17 out of 100. It earned full marks for retraction move, ringing, and repeatability. Overhang efficiency was robust, reaching 70° earlier than defects. That is nicely above the everyday 60° restrict of most FDM techniques.

3DPI take a look at outcomes and radar chart for Silent mode. Pictures and pictures by 3D Printing Trade.

The Balanced mode take a look at was accomplished in 4 hours and 10 minutes. Surprisingly, it outperformed the Silent mode with an excellent rating of 95.65 out of 100, surpassing most competing FDM techniques. This end result ranks among the many high three scores we’ve recorded in our in depth 3DPI testing, a outstanding achievement for such an reasonably priced machine.

Elegoo’s 3D printer earned full marks within the rectangular and round pyramid sections, demonstrating well-tuned stress advance and extrusion settings. It additionally excelled in move, retraction, ringing, and repeatability assessments, delivering extremely correct and constant outcomes.

3DPI take a look at outcomes and radar chart for Balanced mode. Pictures and pictures by 3D Printing Trade.

Lastly, Ludicrous Mode accomplished the print in simply 3 hours and 10 minutes. Importantly, this mode locations vital stress on the belts on account of excessive acceleration and deceleration forces, which might result in sooner put on and diminished longevity of mechanical parts.

Ludicrous Mode delivered a formidable rating of 90.45, proving that high-speed 3D printing can nonetheless produce wonderful outcomes. All bridge options have been executed flawlessly, outperforming the Silent and Balanced mode prints. Repeatability in ringing, move, and retraction assessments was additionally spot-on. Whereas minor defects appeared on the 60° overhang mark, this nonetheless matches the anticipated efficiency of most desktop FDM techniques. Total, the Elegoo Centauri Carbon is a best choice for customers looking for high-speed 3D printing with out compromising 3D print high quality.

3DPI take a look at outcomes and radar chart for Ludicrous mode. Pictures and pictures by 3D Printing Trade.

Testing Elegoo Centauri Carbon 3D printer purposes

Subsequent, our staff evaluated the Centauri Carbon’s efficiency in real-world purposes. Elegoo’s low-cost, entry-level system is geared towards hobbyists and makers, lots of whom produce small miniatures and high-resolution fashions.

We 3D printed an in depth dragon mannequin from MakerWorld, that includes intricate textures and sharp spikes. Utilizing PLA and tree helps generated within the Elegoo Slicer, the mannequin printed efficiently on the primary try. The outcomes have been spectacular. All superb particulars have been captured cleanly, with no seen defects, making the Centauri Carbon a superb selection for small-scale modeling.

3D printed dragon mannequin. Pictures by 3D Printing Trade.

We additionally 3D printed an ornamental plant pot in PLA. Our first try failed, regardless of the filament being correctly loaded. The touchscreen turned unresponsive, stopping a pause and suggesting a doable firmware crash, a problem we hadn’t encountered earlier than. Energy biking the printer and clearing the construct plate resolved the issue.

The second print accomplished efficiently in 5 hours, exhibiting wonderful floor high quality with constant layers. The 3D printer’s cooling system successfully prevented defects, permitting overhangs to print with out distortion.

The failed (orange) and profitable (inexperienced) 3D printed plant pots. Pictures by 3D Printing Trade.

Customers may additionally want to fabricate personalized upgrades for automotive purposes. The Centauri Carbon’s broad materials compatibility makes it notably enticing for these use instances. Our staff used high-strength and sturdy ASA-CF filament to 3D print a useful airbox consumption lid.

This take a look at achieved a seamless 3D printing course of and distinctive half high quality. Embossed textual content and pictures have been seen, whereas the floor high quality was clean with no widespread defects like warping and layer misalignment. The sleek layers underscore the system’s correct mattress levelling capabilities.

3D printed airbox consumption lid. Pictures by 3D Printing Trade.

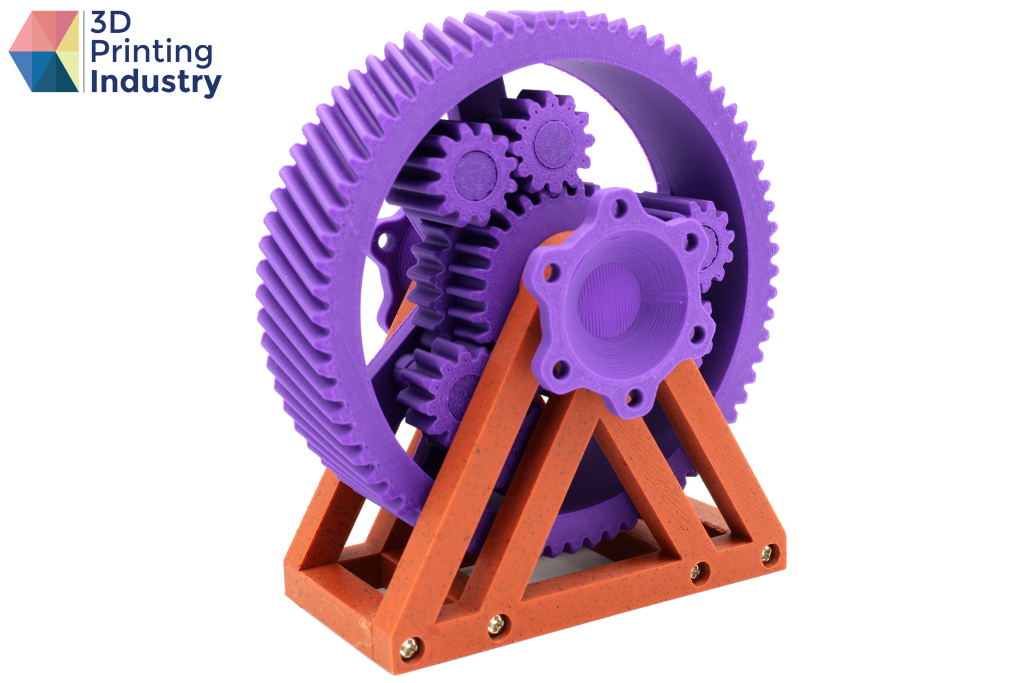

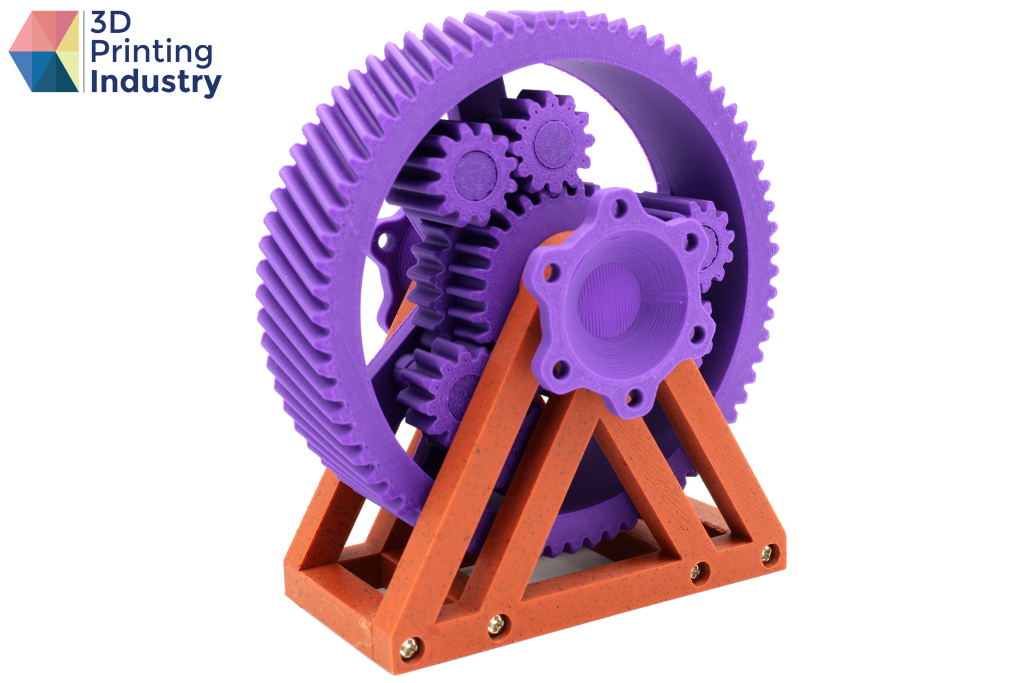

Potential prospects may additionally want to fabricate geometrically correct, useful parts. To evaluate the Centauri Carbon’s suitability for these purposes, we 3D printed a useful ABS spur gear meeting consisting of 20 elements.

All elements have been produced in simply six hours. As soon as assembled, the gear exhibited flawless performance, highlighting the distinctive high quality and accuracy of all 20 3D printed parts. The gears interlock exactly, permitting for environment friendly pressure transmission and optimum system efficiency. We have been impressed by this end result, as competing 3D printers typically battle with mattress adhesion, resulting in poor performance.

Can the Elegoo Centauri Carbon deal with extra superior engineering supplies for light-weight, high-strength purposes? To search out out, we fabricated a generative design bracket utilizing PC-CF filament, recognized for its high-temperature 3D printing necessities and propensity for clogging.

Elegoo’s low-cost 3D printer once more carried out exceptionally. The half was accomplished in 5 hours with excellent precision, demonstrating spectacular dimensional accuracy and floor high quality for such a difficult geometry. Layer adhesion was robust, with no indicators of warping, delamination, or extrusion inconsistencies. Secure temperature management and exact move administration have been maintained all through, validating the Centauri Carbon’s suitability for superior engineering purposes.

3D printed generative design bracket. Pictures by 3D Printing Trade.

Elegoo Centauri Carbon: a brand new commonplace for low-cost FDM 3D printing

The Centauri Carbon units a brand new benchmark within the low-cost desktop FDM 3D printer market. It combines affordability with spectacular user-friendliness, making it a really perfect entry level into 3D printing. Options like automated mattress leveling, Z-offset adjustment, resonance frequency detection, and nozzle cleansing guarantee a clean, hassle-free workflow.

Excessive-speed 3D printing is a well-liked development amongst client 3D printers, with many sacrificing print high quality for spectacular top-speed stats. Elegoo’s Centauri Carbon goes past this trade-off. It’s Ludicrous mode combines spectacular 3D printing accuracy, precision, and floor high quality with slashed printing instances. The 90.45 Ludicrous 3DPI rating is spectacular amongst any FDM system. Its 95.65 rating in Balanced mode ranks among the many highest 3DPI take a look at outcomes recorded.

Our testing revealed distinctive accuracy and precision. For repeatability, the desktop 3D printer achieved a formidable common distinction of 0.025 mm throughout all measurements, with a imply commonplace deviation of 0.012 mm. Each outcomes fall nicely beneath our benchmarks of 0.1 mm and 0.05 mm, respectively.

Elegoo’s enclosed construct chamber marks a major step ahead in materials compatibility. It demonstrated a capability to keep up a secure, heated surroundings, which minimized defects when printing with high-performance filaments like PC-CF and ASA-CF.

Our engineering staff recognized a number of minor areas for enchancment. The shortage of job queuing performance within the slicer is irritating when attempting to execute a number of 3D print jobs again to again. Elegoo’s FDM slicer additionally lacks a skip half function, that means {that a} failed half impacts the complete print job. This will trigger catastrophic 3D print failures and waste materials.

Total, we have been very impressed by the Elegoo Centauri Carbon’s versatility and high quality. Regardless of its low value and entry-level focus, the system delivers excellent outcomes. Spectacular high-speed capabilities put the 3D printer on par with dearer machines, making it a compelling selection for hobbyists and engineers looking for high-performance 3D printing on a finances.

Technical specs of the Elegoo Centauri Carbon

| 3D Printing Expertise | FDM (Fused Deposition Modeling) |

| 3D Print Quantity | 256 mm x 256 mm x 256 mm |

| 3D Printer Dimensions | 398 mm x 404 mm x 490 mm |

| 3D Printer Weight | 17.5 kg (35.274 lbs) |

| 3D Printing Precision | ±0.1 mm |

| Nozzle Diameter | 0.4 mm |

| Filament Diameter | 1.75mm |

| Most Extruder Temperature | 320°C |

| Heated Construct Plate Temperature | As much as 110°C |

| Most 3D Printing Pace | 500 mm/s |

| Most Acceleration | 20,000 mm/s² |

| Most Hotend Stream | 32 mm/s² |

| Extruder Amount | One |

| Extruder Sort | Direct Drive |

| Layer Thickness | 0.1-0.4 mm (advisable 0.2 mm) |

| Slicer Compatability | Elegoo Slicer (advisable), Orca, Cura |

| Connectivity | USB & Wi-Fi |

| Enter Voltage | 100-240 VAC, 50/60 Hz |

| Materials Compatability | ABS, ASA, PLA, PLA-CF, PETG, TPU, PLA-CF, PETG-CF, ABS-CF, ASA-CF, PET-CF, PA-CF, PET, PC, PC-CF, and PA |

Take the 3DPI Reader Survey — form the way forward for AM reporting in beneath 5 minutes.

Who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to maintain up with the newest 3D printing information.

You may also observe us on LinkedIn, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits the Elegoo Centauri Carbon 3D printer. Picture by 3D Printing Trade.