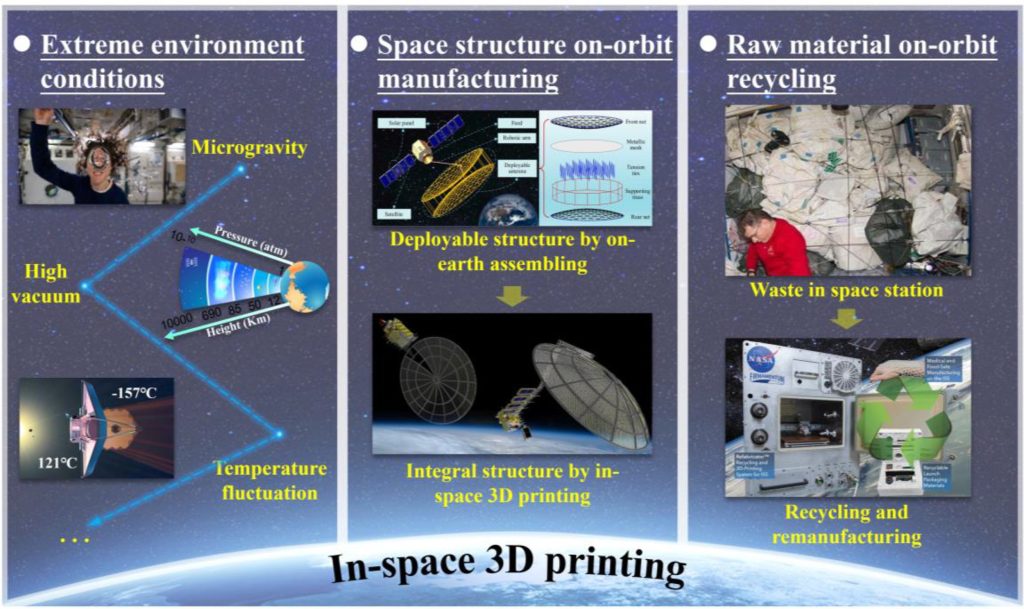

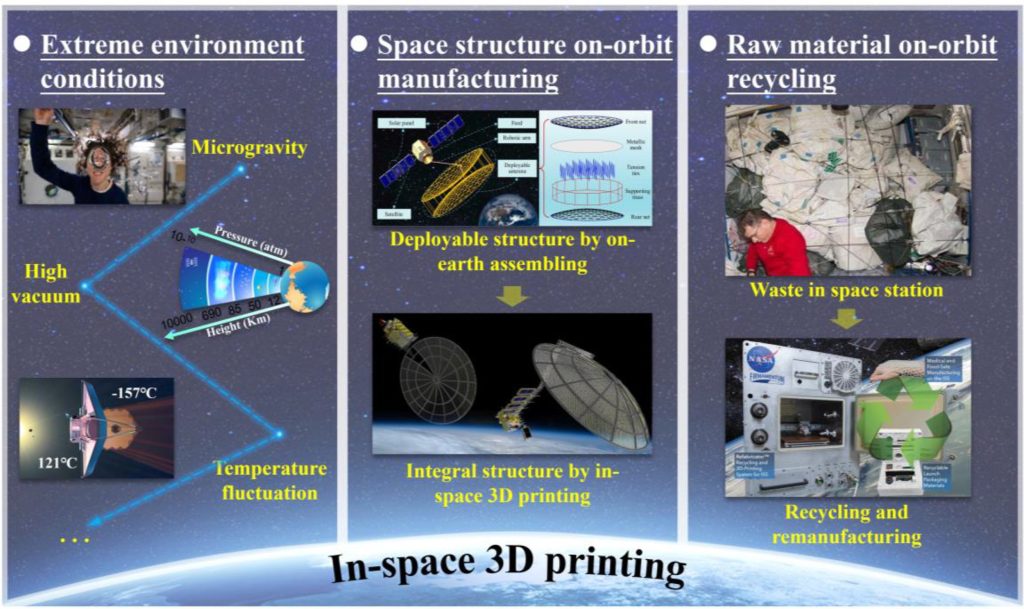

A brand new assessment revealed on ScienceDirect by researchers from Xi’an Jiaotong College and the China Academy of House Know-how offers an in depth account of in-space 3D printing progress utilizing polymers and fiber-reinforced composites. The doc identifies in-situ additive manufacturing as a transformative method to fabricating house constructions, bypassing launch constraints and enabling fast manufacturing of instruments, parts, and enormous assemblies straight in orbit.

Additive manufacturing in house addresses challenges related to payload mass, onboard spares, and launch geometry. Conventional fabrication strategies depend on Earth-based meeting adopted by launch, incurring prices exceeding $10,000 per kilogram. Constructions are restricted in dimension by payload fairings, and launch overloads require extreme design redundancy. In distinction, 3D printing in orbit permits for light-weight, structurally environment friendly designs. Thermoplastic polymers, notably fiber-reinforced variants, are favored as a consequence of their low processing temperatures, excessive strength-to-weight ratios, radiation resistance, and recyclability.

Microgravity and vacuum are two principal circumstances affecting printability in house. The assessment identifies Fused Filament Fabrication (FFF) as essentially the most viable method below microgravity as a consequence of its use of stable filament feedstock and absence of free-flowing liquids or powders. NASA first examined extrusion-based 3D printing aboard a parabolic flight in 1999 utilizing ABS. Subsequent campaigns by Made In House Inc. (MIS) led to the primary on-orbit prints aboard the Worldwide House Station (ISS) in 2014. MIS and NASA produced over 200 components on ISS utilizing ABS, Ultem 9085, and HDPE.

Experimental comparisons confirmed negligible mechanical degradation in microgravity-printed specimens. For instance, below 1g, ABS specimens exhibited a tensile energy (Xt) of 23.86 MPa, modulus (Et) of 1.52 GPa, and compressive energy (Xc) of 51.37 MPa. Microgravity prints confirmed Xt of 25.03 MPa, Et of 1.45 GPa, and Xc of 43.37 MPa. Dimensional variation (DV) remained between -0.3 mm and +0.13 mm. PLA components printed by the European House Company (ESA) and German Aerospace Heart (DLR) throughout parabolic flight confirmed most layer heights of 0.26 mm in 0g in comparison with 0.16 mm on Earth, but tensile energy remained above 33 MPa in each circumstances.

The absence of gravity eliminates hydrostatic strain, disrupting typical materials circulate. Floor rigidity turns into the dominant drive, rising the danger of soften fracture and spherical bead formation. A continuity criterion proposed by Crockett et al. established that nozzle peak ought to stay below π occasions the nozzle diameter to make sure constant filament deposition. Hafley et al. confirmed that exact nozzle-substrate distance management preserved print continuity in microgravity.

Vacuum circumstances introduce thermal management challenges by eradicating convective cooling. Warmth switch depends on conduction and radiation, slowing cooling charges and altering temperature gradients. Spicer et al. at Virginia Tech developed a vacuum-compatible hotend with titanium warmth breaks and radiative warmth sinks, sustaining operational stability at 390 °C whereas maintaining feedstock temperatures under 85 °C. Utilizing this method, over 100 practical components had been printed in PEKK, PEI, and carbon nanotube-reinforced variants below 0.01 Pa.

Simulated vacuum exams revealed important efficiency variations. PEEK components printed at 100 Pa exhibited 212.5% increased tensile energy within the V-90 course in comparison with atmospheric specimens (10.0 MPa vs 3.2 MPa), indicating improved interlayer bonding. Nevertheless, H-0 and H-90 SCF/PEEK specimens printed in vacuum confirmed 6.3% and 29.7% decrease tensile energy respectively, as a consequence of porosity. Microstructural evaluation discovered 28.91% porosity in vacuum SCF/PEEK in comparison with minimal ranges in pure PEEK, attributed to swelling of closed air pores throughout extrusion.

Outgassing is a vital constraint. NASA requires TML

Structural functions of in-space 3D printing deal with two classes: particles shielding and truss frameworks. A variable-density lattice defend developed by Gabriel et al. used Ultem 1010 and 9085, with angled inside panels to deflect particles clouds. In hypervelocity exams, it efficiently absorbed a 4 mm aluminum projectile at 5.2 km/s. Spiderfab, developed by Tethers Limitless, fabricated triangular truss items utilizing SCF/PEEK tapes through heated die pultrusion. A ten-meter truss weighing 340 g was constructed at 15 cm/min. Redwire’s OSAM system produced a 37.5-meter Ultem 9085 truss utilizing reciprocating push-based deposition. Beneath vacuum, fabrication of 850 mm segments was validated.

In-space recycling is critical to keep up materials shares for long-duration missions. The Refabricator, developed by Tethers Limitless and deployed on ISS in 2018, recycled Ultem 9085 in a closed-loop cycle. After six print/recycle iterations, tensile energy elevated by ~10%, although pressure at fracture dropped 20%. A second system, Recycler, adopted the same melt-extrusion mannequin.

For fiber-reinforced composites, researchers applied a reverse melting course of utilizing infrared heating. In vacuum (100 Pa), fiber bundles had been separated from molten PEEK resin and redrawn into filaments. Remanufactured CCF/PEEK composites confirmed a tensile energy of 233.8 MPa and modulus of 25.16 GPa—each barely increased than the unique (228.2 MPa and 23.42 GPa). Flexural modulus was 1.5× increased. Microstructural inspection confirmed improved resin impregnation and lowered voids as a consequence of higher fiber wetting throughout remanufacture.

The assessment identifies 4 areas requiring additional analysis: correct simulation of multi-condition house environments, structural design tailor-made to microgravity stiffness constraints, autonomous on-orbit meeting utilizing robotic techniques, and multifunctional structural integration utilizing multi-material printing. Most notably, long-term publicity to temperature swings, atomic oxygen, and radiation—solely briefly explored up to now—stays a limiting unknown.

Need to assist select the 2025 3DPI Awards winners? Be part of the Professional Committee as we speak.

Prepared to find who gained the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to remain up to date with the newest information and insights.

Featured picture reveals exterior publicity and post-flight materials testing. Picture through ScienceDirect.