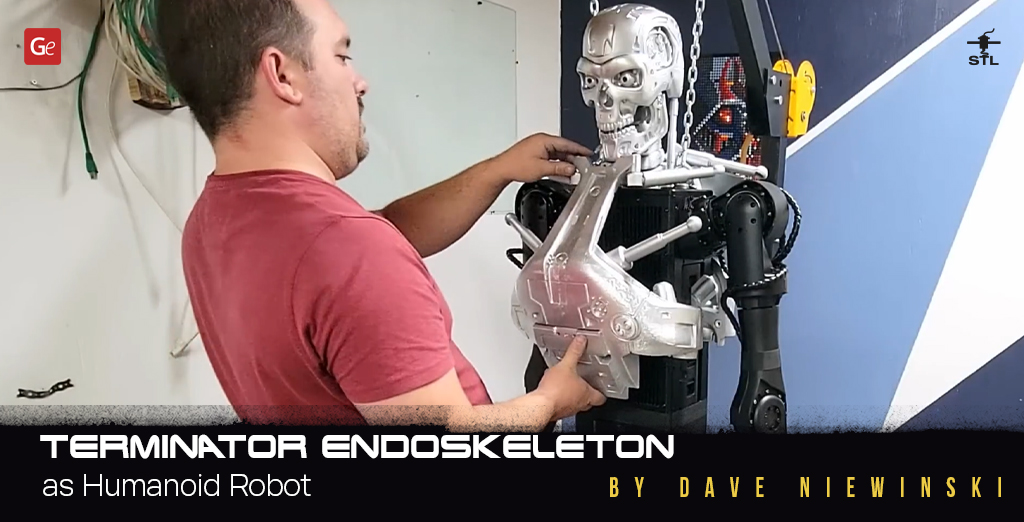

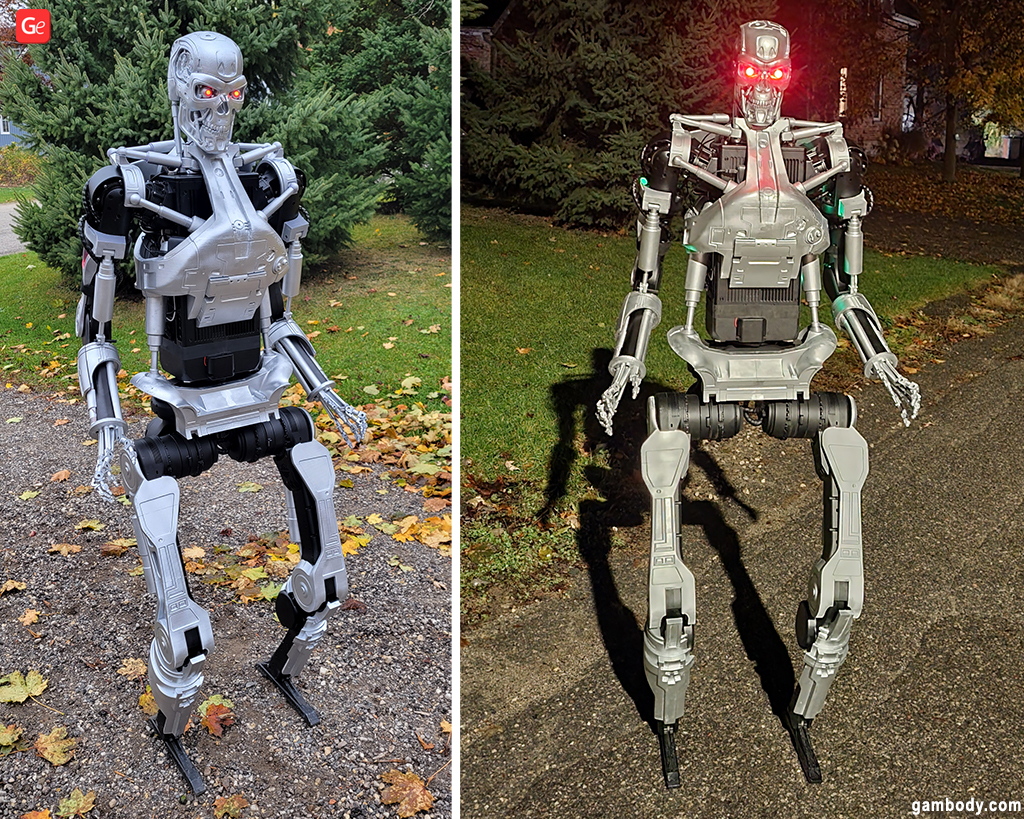

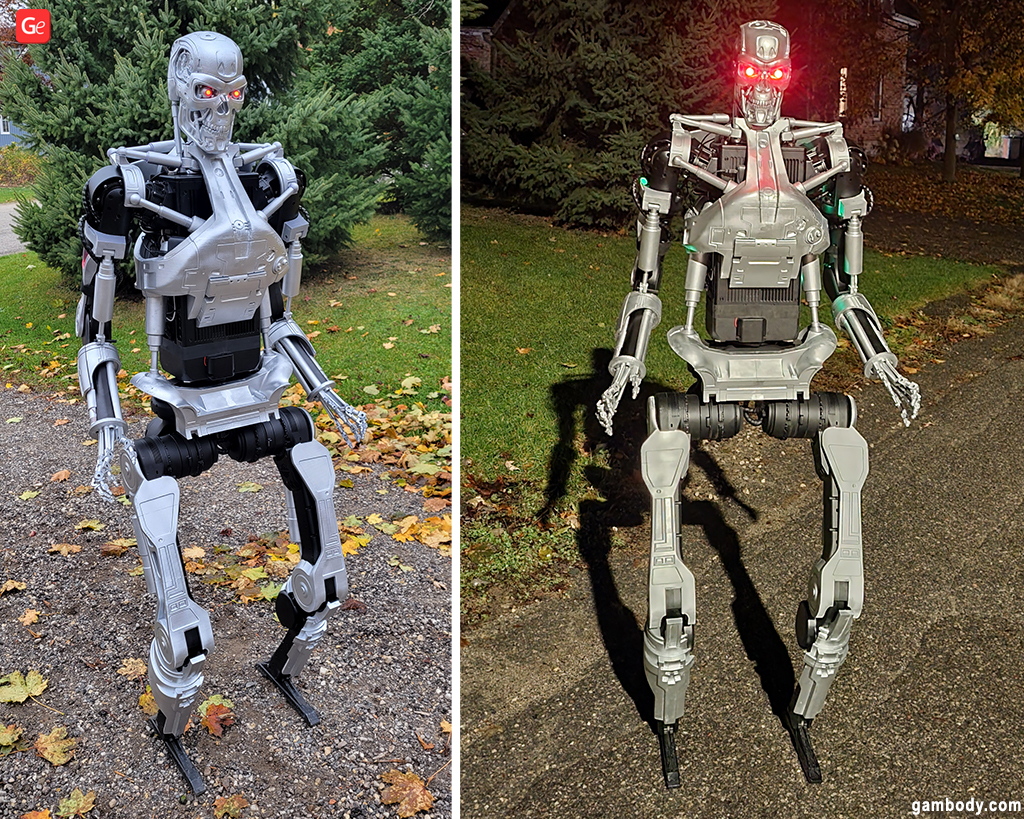

Think about a 3D printed Terminator Endoskeleton strolling round your neighborhood and peering by your night home windows! Robotics engineer and 3D printing fanatic Dave Niewinski from Dave’s Armoury YouTube channel created essentially the most spectacular nightmare animatronic utilizing his humanoid robotic Unitree H1 and T-800 Endoskeleton STL recordsdata from Gambody market.

The undertaking appears epic! Not solely did it shock Dave’s neighbors, but it surely additionally proved how unimaginable a 3D printer and its potentialities are. Possessing astonishing engineering expertise and vivid creativeness, you possibly can 3D print a personality from plastic, making a one-of-a-kind expertise for the entire world to witness.

Fortunately, Dave Niewinski agreed to share extra particulars about his real-life Endoskeleton experiment with Gambody readers (and you might be welcome to look at the unique video of how this T-800 was constructed to suit the humanoid robotic).

1. Dave, are you able to please introduce your self and share some background on the way you started 3D printing?

I’m Dave Niewinski, a robotics engineer from Canada. I began with industrial robotics integration and am now in AI and extra cutting-edge growth. 3D printing is a necessary a part of that course of. It permits me to prototype and iterate on options rapidly.

2. How large is Dave’s Armoury workforce? Who helps you construct your distinctive tasks and make movies?

Dave’s Armoury is simply me. I put on all of the hats for now, however I most likely ought to look into increasing the workforce.

3. How and when did Unitree H1 Robotic transfer to your home? Does it stick with your loved ones and entertain your neighborhood?

I’ve solely had Stanley (the identify of Dave’s humanoid robotic) for a few month. It lives within the lab and usually walks round my city to go to the neighbors.

4. Whose concept was to call the Unitree Humanoid Stanley earlier than you flip him into Terminator T-800 Endoskeleton?

I feel it was really my mother’s concept. I wasn’t offered on the identify, however I discussed it in a gathering, and the identify simply caught.

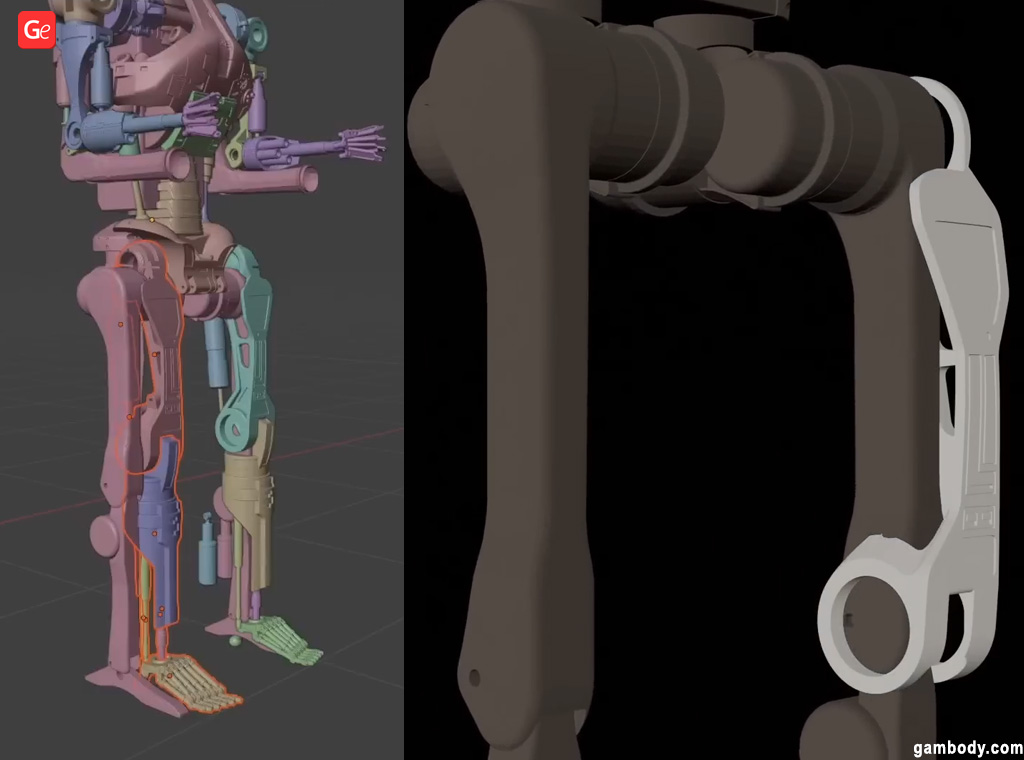

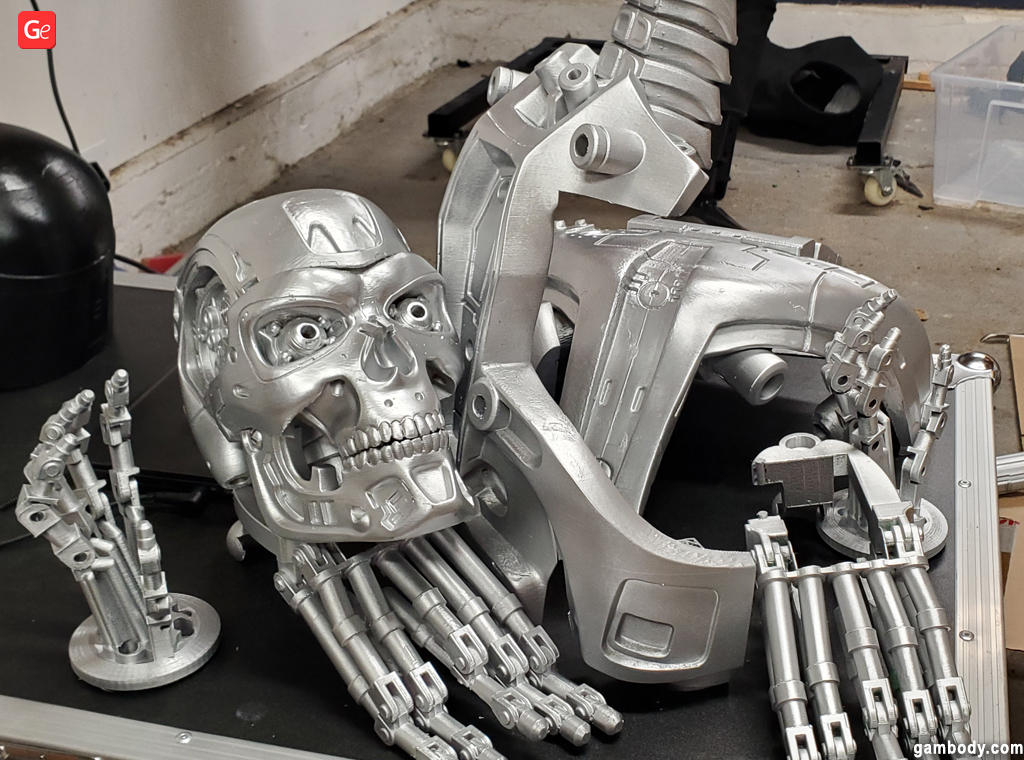

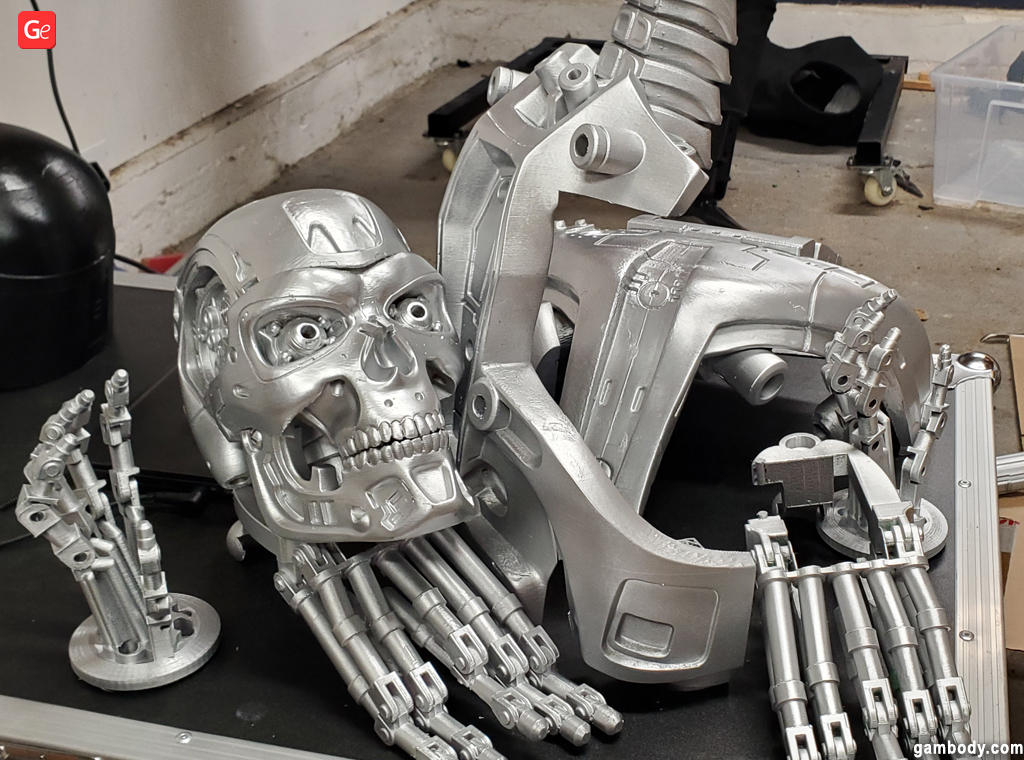

David downloaded T-800 Endoskeleton STL recordsdata from gambody.com and spent lots of time redesigning them to suit the humanoid robotic physique and create some of the spectacular Terminator fashions. You received’t discover such a implausible animatronic Endoskeleton on the market on common marketplaces. Nonetheless, you may also use Terminator T-800 Endoskeleton recordsdata for 3D printing to make your distinctive undertaking. It’s possible you’ll even construct your model of a nightmare animatronic to scare your neighborhood the following Halloween!

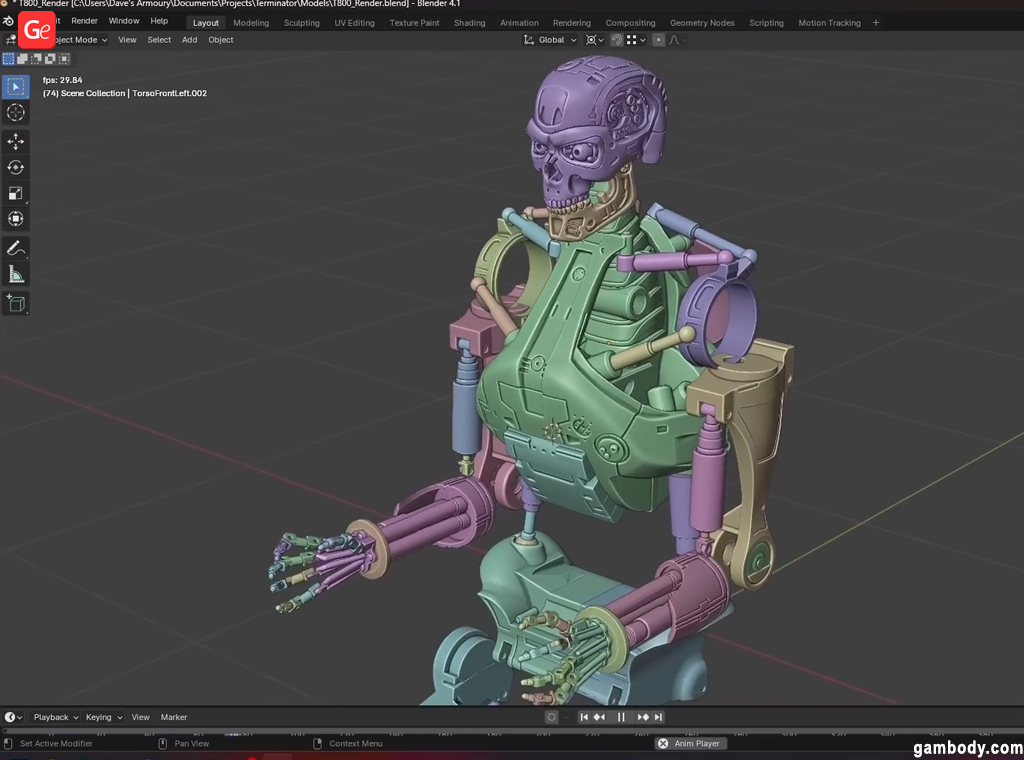

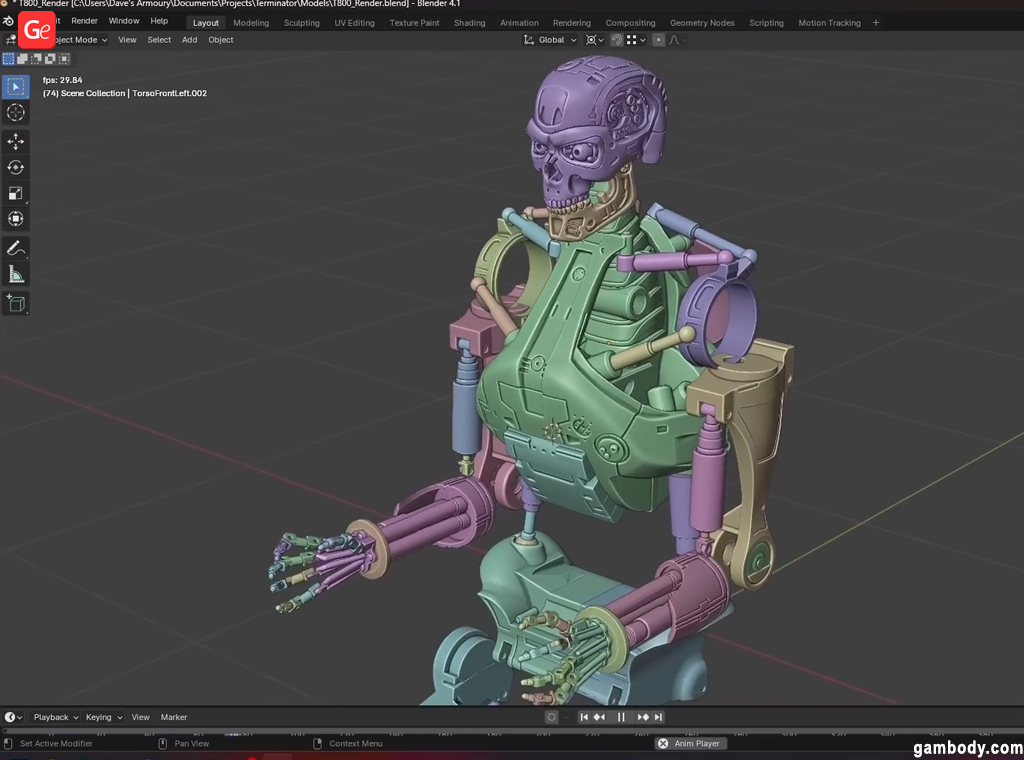

5. How did you want upscaling and making use of the boolean device to Gambody STL recordsdata of the Terminator Endoskeleton?

This 3D printing mannequin may be very detailed, so the recordsdata scaled effectively. Most of them have been manifold meshes, so boolean labored effectively. Some wanted just a little cleanup, although. Not an issue for 3D printing, however a bit of labor for one thing like this.

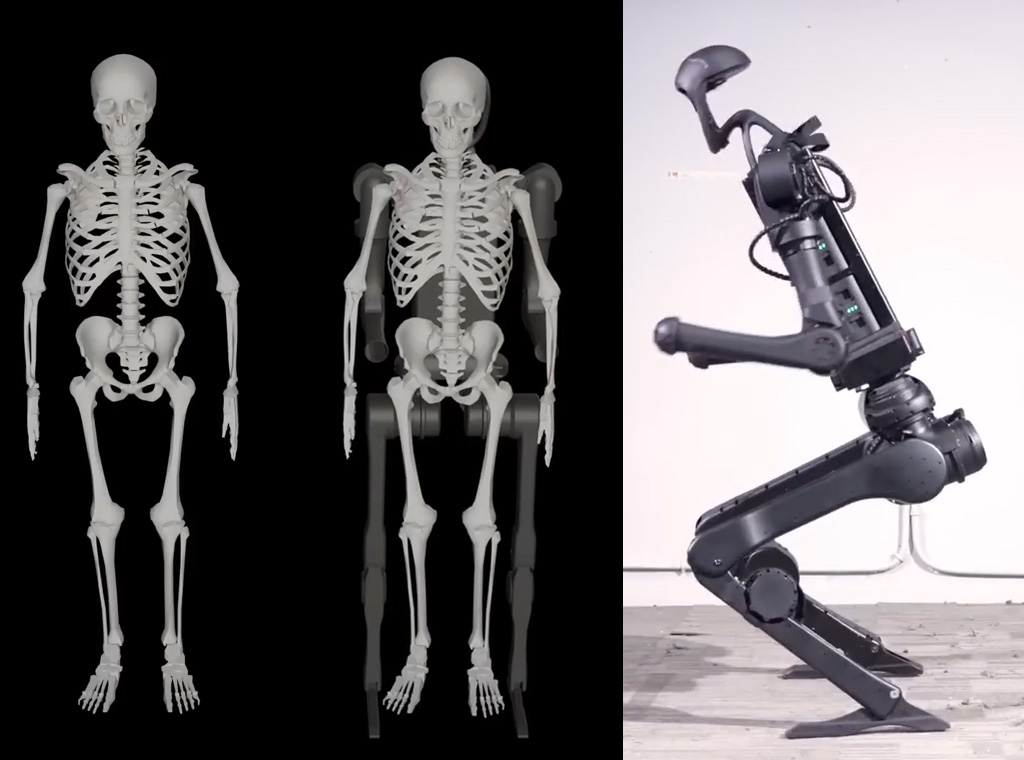

6. Do you bear in mind what number of days you spent working in Blender to regulate each T-800 Endoskeleton STL file based on the life-size Unitree Robotic?

Too many. In all probability near per week. Quite a lot of the problem got here from making the items match because the humanoid robotic moved them round. Slicing out a static mannequin is simple, however reducing out one thing that’s going by a spread of motions is way trickier.

7. How exhausting is the adjusting course of in actuality? What talent stage does a hobbyist have to repeat one thing related?

The method is pretty easy. It simply takes lots of handbook work. Being comfy in Blender could be important. There actually isn’t a lot “robotics” on this undertaking.

Learn additionally: Free STL Editor: Find out how to Edit and Restore STL Recordsdata (3D Fashions).

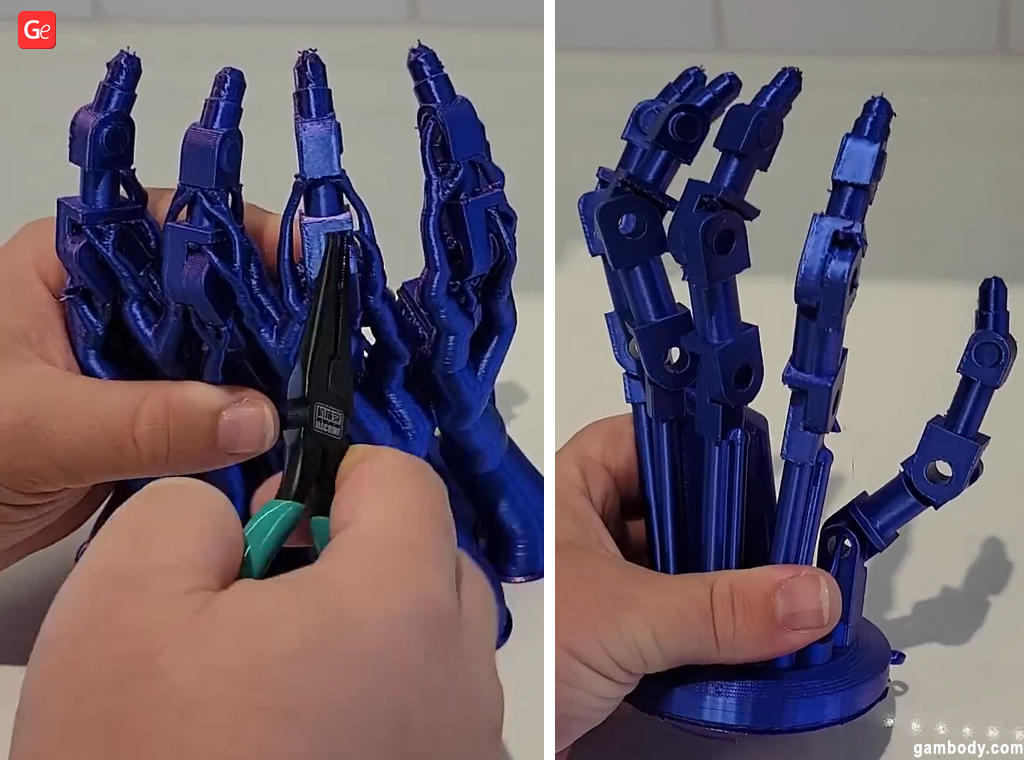

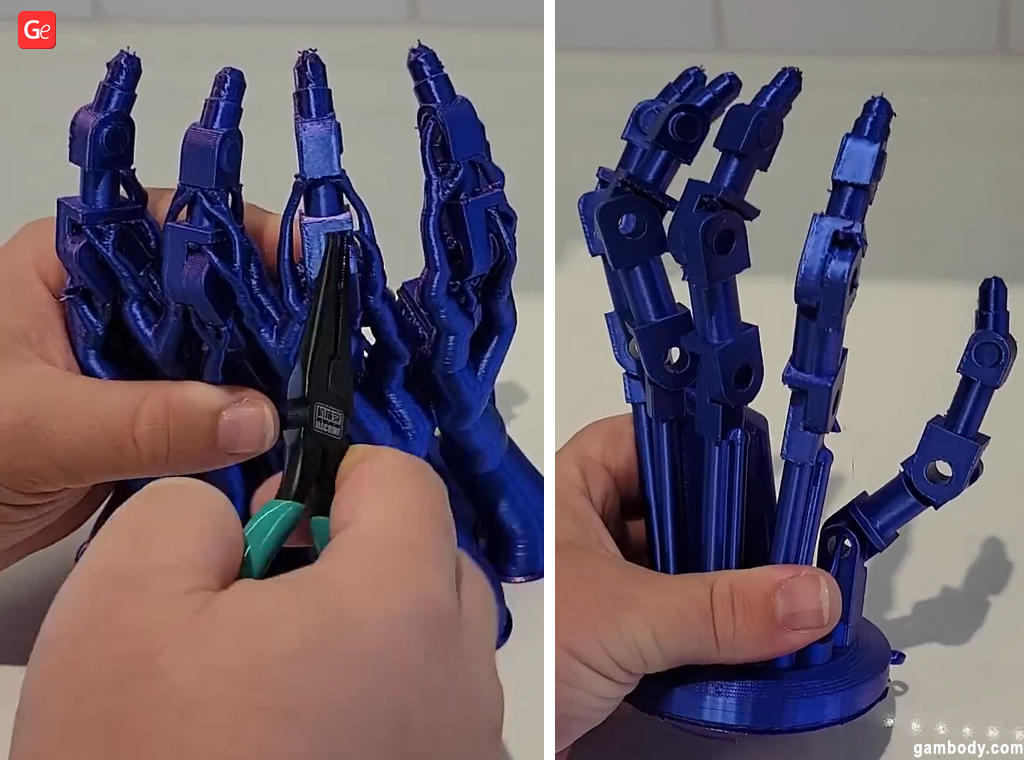

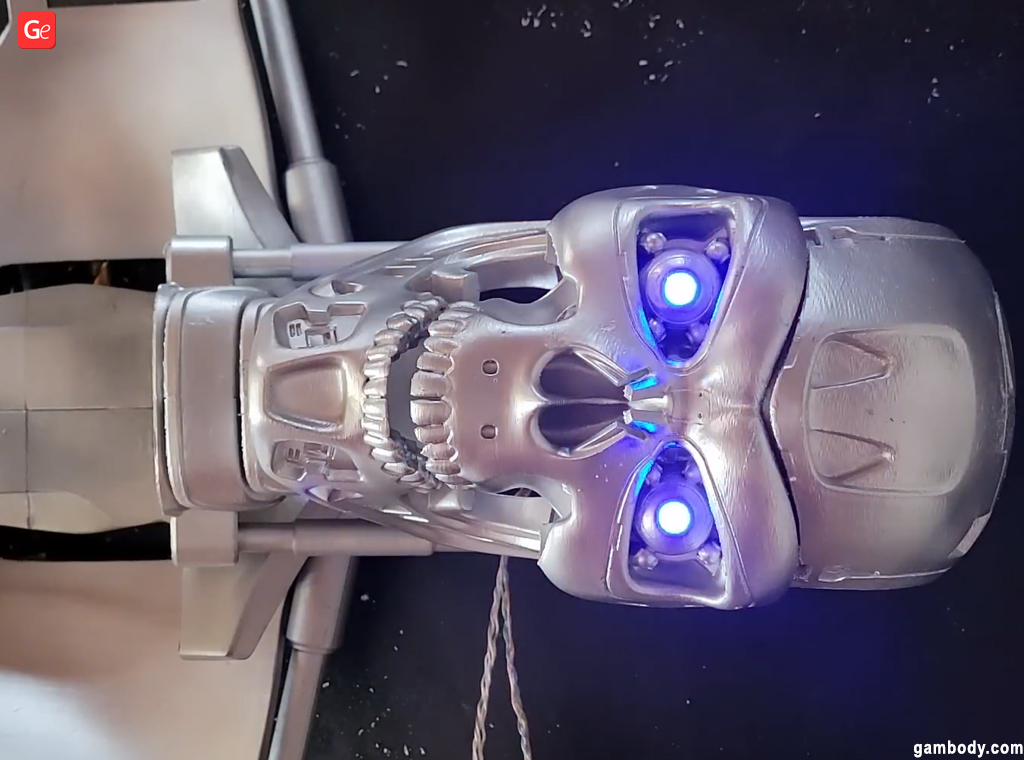

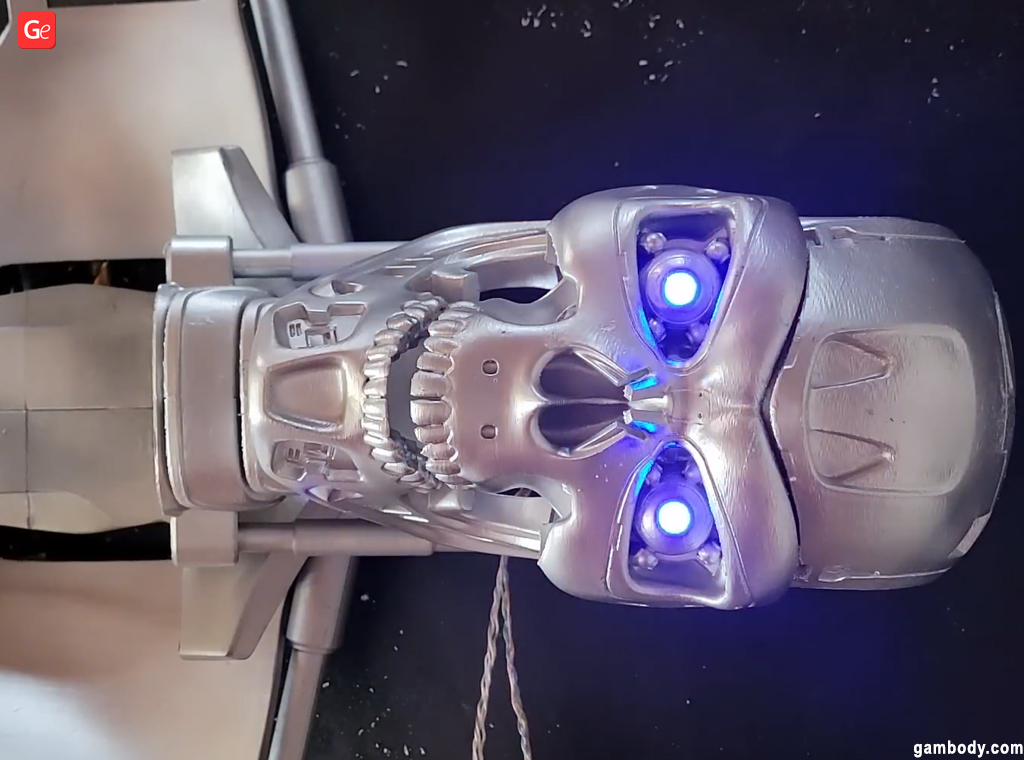

T-800 Endoskeleton 3D print consists of 129 components in case you have an FDM/FFF 3D printer. The unique mannequin has ratchet mechanisms for knee and elbow bending, ball-and-claw joints for wrist and head rotations, area for LED lights to mild up the eyes, and different unimaginable action-ready components. Thus, in the event you don’t have a humanoid robotic like Unitree H1, you possibly can nonetheless make this Terminator undertaking and find yourself with a implausible piece for show.

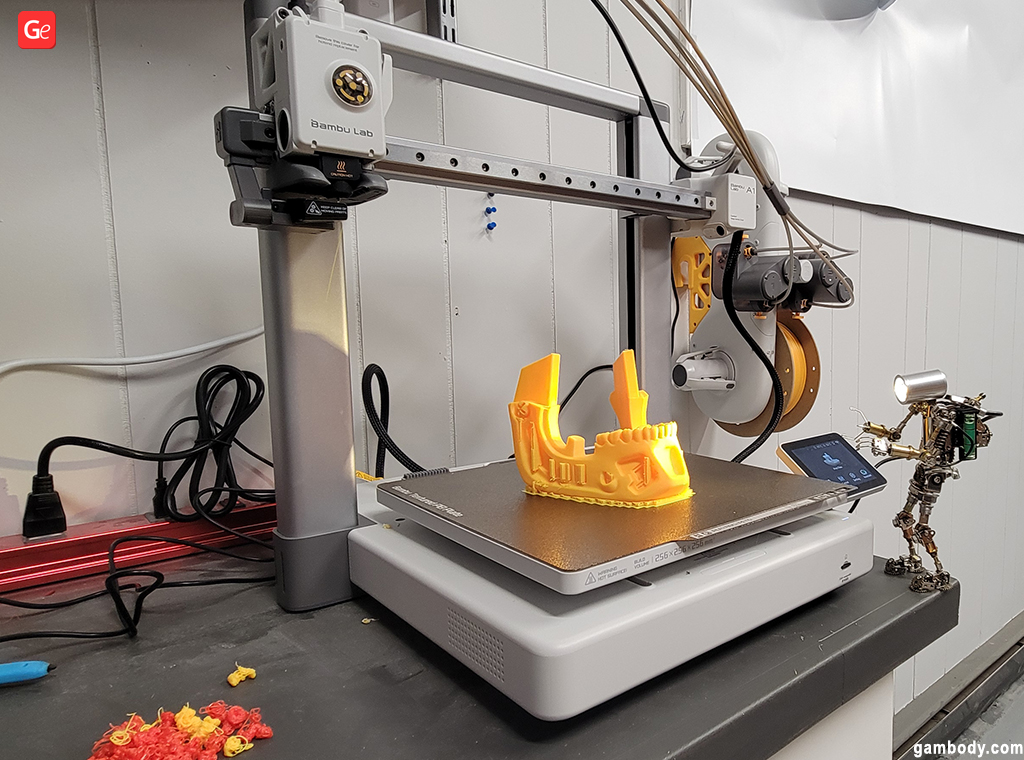

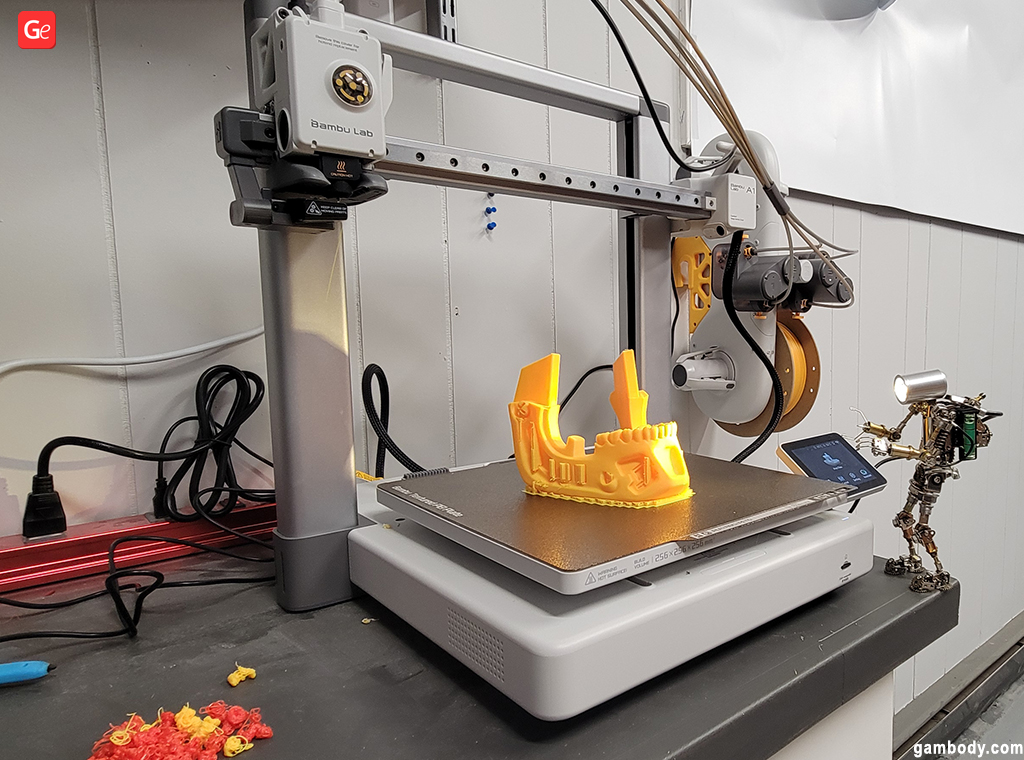

8. Was T-800 Endoskeleton 3D print the primary mannequin you printed with Bambu Lab A1 and Bambu Lab A1 mini 3D printers, or did you run some assessments beforehand?

I bought the 2 Bambu 3D printers proper initially of the undertaking, so I jumped straight into manufacturing.

9. What number of 3D printers did you find yourself utilizing to construct the T-800 Endoskeleton?

I used my three printers (2 x Bambu and 1 x Lulzbot). I feel James used 8 Bambu printers at his store.

10. What number of filament spools did you utilize for this Terminator mannequin?

I feel the entire undertaking solely used six rolls. The prints use very mild in-fill since they aren’t structural.

11. What was essentially the most difficult half between 3D printing, eradicating the helps, sanding, portray, and becoming the items in your H1 Robotic?

Sanding is tremendous simple, however takes FOREVER. I preferred placing all of the 3D printed items on the humanoid robotic. It felt like I used to be giving it an improve, regardless that it was simply beauty. Eradicating the helps was a little bit of a ache if I forgot to vary the assist kind.

12. Did you depend all of the items that have been 3D printed or know their weight?

I didn’t. There have been so many 3D printed components that have been being test-fit or up to date that the depend was all the time altering.

13. Had been you upset whenever you found out that your robotic prototype and the true robotic didn’t match as deliberate when you ready all of the 3D prints?

I used to be anticipating one thing like that to come back up. It’s actually frequent with 3D fashions like that as a result of producers don’t launch their full CAD, only a subset that they assume customers will want. Polycam made it very easy to fill within the gaps, although.

14. How difficult was it to 3D scan the robotic and begin the work once more in adjusting the prototype and 3D printed components? What apps did you utilize for this?

Tremendous easy. The scan took a few minutes. Then it was simply importing and aligning all the pieces in Blender. Positively, it’s turning into a part of my workflow for tasks like this sooner or later.

15. What primer and spray paints (model, colours) did you utilize? What number of cans did this Terminator mannequin want?

The primer is gray Painter’s Contact. The paint is Aluminum from Premier. Nothing particular, simply what the native ironmongery store had in inventory.

16. How lengthy did it take to color the components and permit them to dry?

The climate was lovely for that week, so I may do all of it exterior. Possibly an hour between the coats.

Learn additionally: Sanding and Portray 3D Prints: Simple Steps.

17. Whose concept was to make use of magnets to clip the back and front components of the 3D printed Endoskeleton to Stanley?

Mine. If I’m taking it aside and reassembling it a number of instances, I don’t need to use one thing like bolts as a result of I’ll want further instruments and might simply strip a gap. Magnets are tremendous easy and low cost.

18. What number of magnets did the undertaking require? How did you discover the right sizes to suit into holes?

There have been solely about 20 magnets in the entire undertaking. Lots of the 3D printed items have been friction-fit onto the humanoid robotic, so that they have been the one ones that wanted to the touch one another and be eliminated. I picked the dimensions based mostly on the most important magnets that would match onto the faces that have been additionally on sale on Amazon.

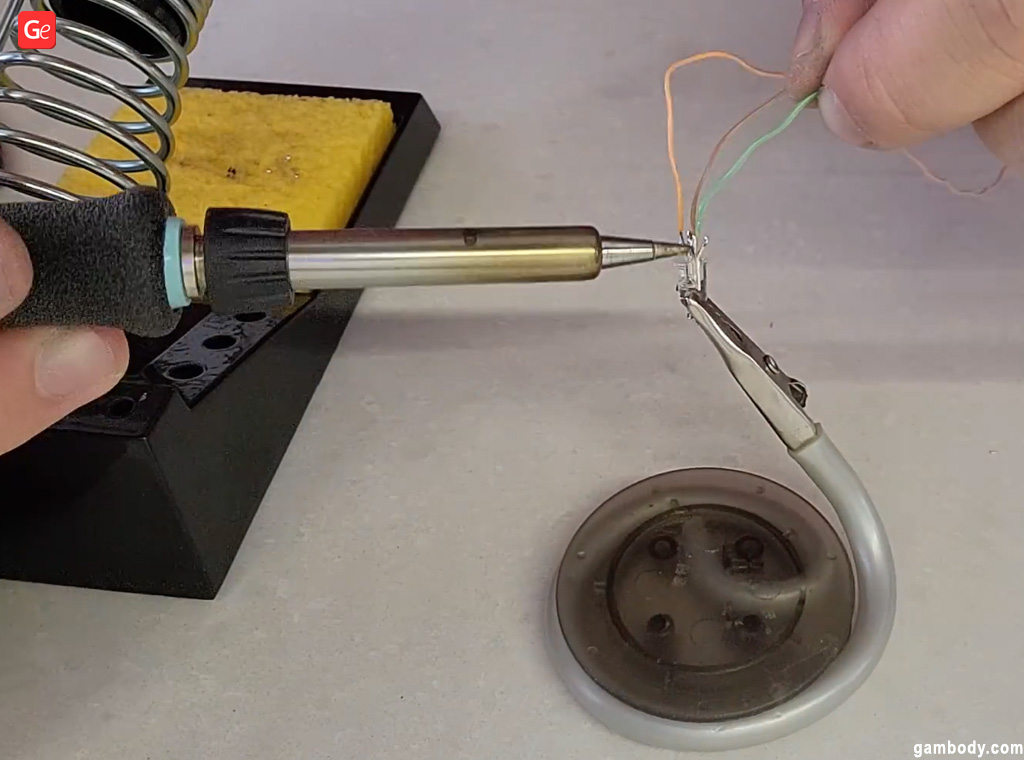

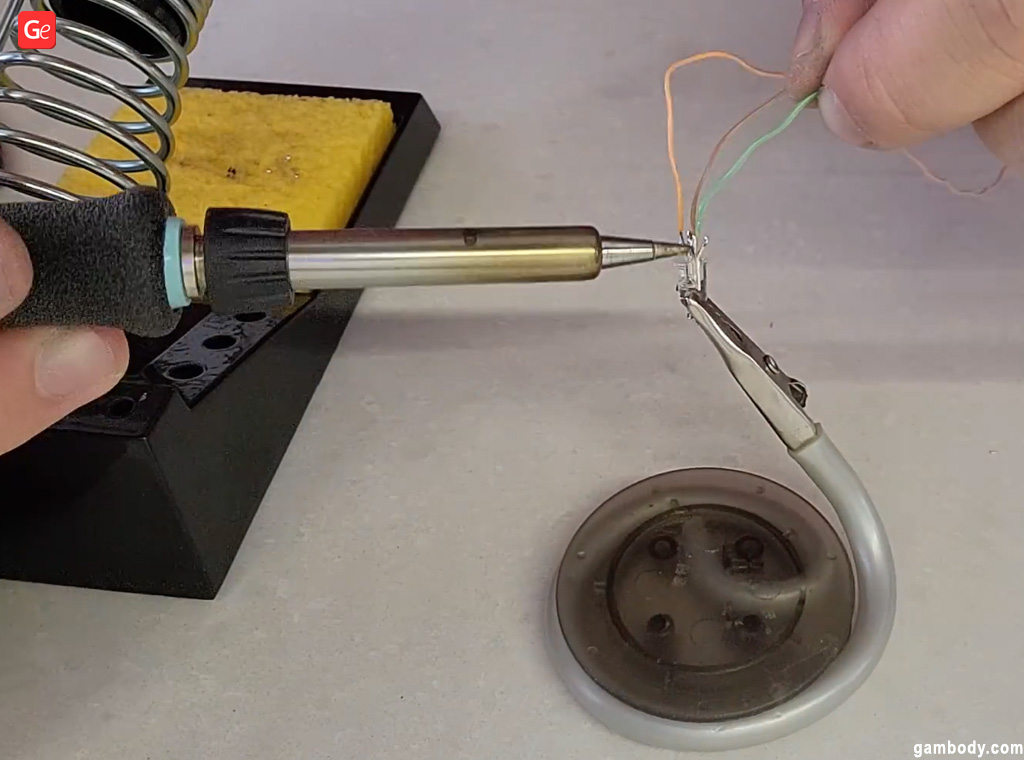

19. Are you able to share extra particulars on the way you modeled and 3D printed pupils and added LEDs to the Terminator’s eyes to make them glow?

The pupils have been simply cylinders with cylinders lower out of them to suit the LEDs. They have been printed with clear PLA filament so the sunshine would shine by but in addition diffuse so that they have been simpler to see.

20. What clear filament did you utilize for the pupils?

Clear PLA. I feel it was from a web based retailer with filaments in Canada.

21. How tough was it to work with all-color-disco-mode LEDs in comparison with common LEDs? How enjoyable was that?

Fairly simple. You simply have 3 inputs for every LED, one for every major shade. I haven’t used them extensively, largely simply instantly wired to make them pink on a regular basis. I plan on reviving the entire undertaking and including some further management/AI to it, which can profit from the multicolor eyes.

Hobbyists select to put in one-color or multicolored LED strip lights of their 3D prints to make them look extra skilled and implausible. Study how one can flip practically each mannequin right into a masterpiece with LEDs. Learn our put up titled Find out how to Put Up LED Lights in a 3D Printed Mannequin.

22. You knew that the Actual Robotic stroll take a look at would fail the 3D printed toes and break them (as a result of the H1 walks very exhausting). What number of makes an attempt did you make earlier than eliminating this characteristic?

Not many. I did want lots of tremendous glue to restore a few of the “hydraulic” items. With the sunshine infill, they ended up being moderately fragile, and I’m clumsy.

Learn additionally: Well-liked 3D Printing Infills: Your Information to Greatest Outcomes.

24. How exhausting was the ultimate meeting of all 3D printed components?

Very simple. The entire items that have been lower down to suit on the print beds have been glued. As soon as they have been entire once more, they have been both friction-fit or magneted onto the robotic. Stanley wants a series hoist to be turned on, which implies transporting and beginning it some other place is tough, and it might must be utterly disassembled so it didn’t break something in transit. Ease of meeting was important.

25. How did folks react when Stanley, aka T-800 or a nightmare animatronic, went for an actual stroll?

It was humorous, it relied on who noticed it. Anybody who watched the film and knew what it was presupposed to be was initially scared. If they’d by no means seen the film earlier than, they weren’t scared and have been very .

26. Your video on turning the H1 Robotic right into a T-800 Terminator Endoskeleton is roughly 13 minutes, giving viewers a sense that it’s a comparatively quick undertaking. What number of months did it actually take?

This undertaking was pretty rushed. I solely had a month to design, 3D print, paint, assemble, file, and edit the entire thing. I really feel that damage the undertaking a bit, however the subsequent model will get extra love.

27. Within the ultimate scenes of your video, Stanley falls, and the 3D printed components break. The place are all these components now? How is Stanley doing right now?

Stanley continues to be working effectively. All 3D printed items have been collected and saved so I can repair them within the new yr.

28. What’s your subsequent 3D printing undertaking?

I’m engaged on the following part of the GlaDOS undertaking, which makes use of some 3D printing. I additionally simply purchased a Groot 3D mannequin from Gambody for a big, non-3D printed undertaking :).

We wish to thank Dave for his time and implausible T-800 animatronic concept! 3D printing fans can watch and rewatch the video in regards to the adventures of a humanoid robotic wearing a Terminator Endoskeleton cosplay. It would encourage extra hobbyists to make use of their 3D printer and Gambody’s STL recordsdata for one-of-a-kind tasks! Please share the photographs and/or movies of your new tasks in our 3D Printing Neighborhood on Fb.

(Visited 968 instances, 1 visits right now)