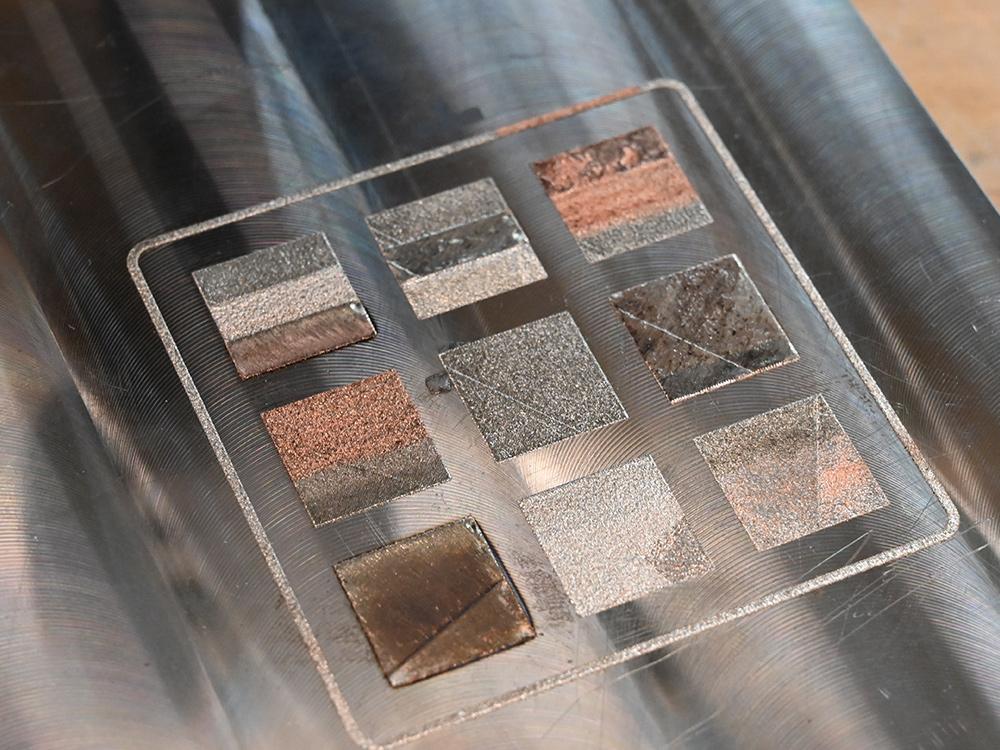

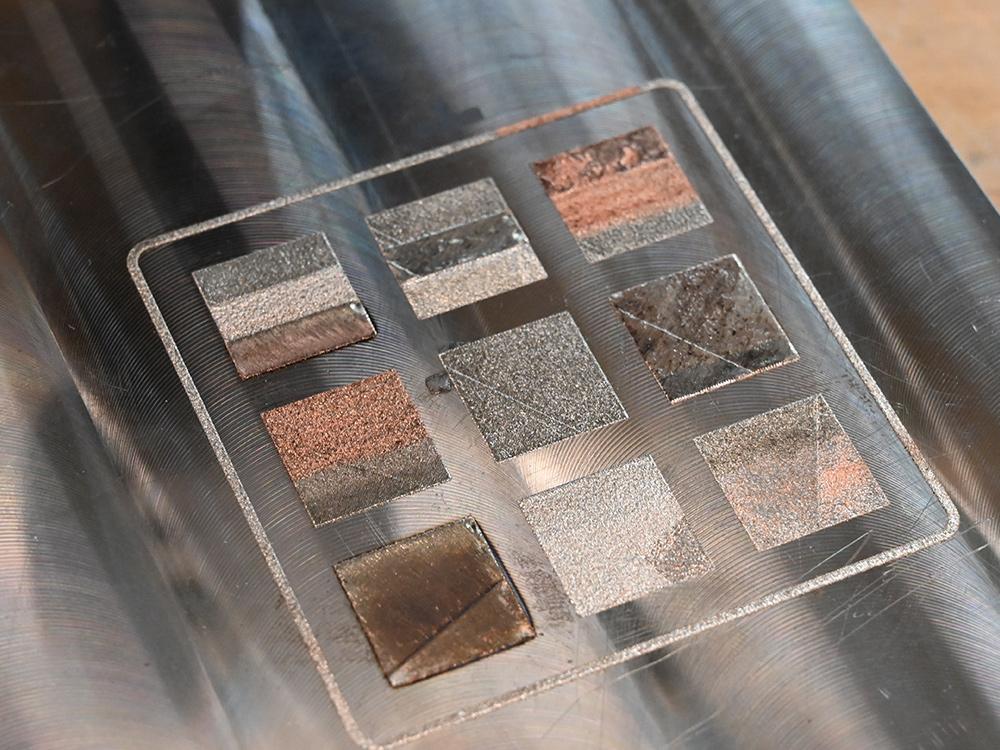

Penn State researchers have developed a brand new multi-material 3D printing approach that efficiently fuses two completely different metals right into a single complicated construction. The staff used a course of referred to as multi-material laser powder mattress fusion to print a construction combining low-carbon chrome steel and bronze. This achievement was made attainable by way of Penn State’s Heart for Revolutionary Supplies Processing By Direct Digital Deposition (CIMP-3D), which acquired an Aerosint selective powder deposition system in August 2023.

“In a course of referred to as selective powder deposition, we will now soften a number of powdered metals in a single layer throughout the additive manufacturing course of — and we have been the primary college within the U.S. to take action,” mentioned Jacklyn Griffis, doctoral candidate in mechanical engineering and first writer of the paper revealed in npj Superior Manufacturing.

The researchers centered on analyzing how construct orientation affected the standard of the ultimate product. They created a posh form generally known as a gyroid, which has functions in warmth exchangers and biomedical implants. The staff examined defects equivalent to cracking and porosity, interfacial microstructures, and aspect diffusion throughout the interface to know how these elements impacted efficiency.

“Penn State has at all times been a pacesetter in steel additive manufacturing, however we now have the power to fabricate complicated multi-material elements, the place we cannot solely make complicated designs however management exactly the place every materials is positioned,” defined Guha Manogharan, affiliate professor of mechanical engineering and co-director of CIMP-3D.

The analysis staff makes use of CT scans to provide digital 3D renderings of elements, permitting them to determine potential points like pores and micron-scale defects. This functionality allows real-time monitoring of the manufacturing course of. Based on Griffis, a one-centimeter-tall steel half consists of hundreds of layers of steel powder and takes a number of hours to print.

Future work will deal with remodeling this 3D printing methodology right into a extra strong, production-ready course of by way of in-process monitoring. The staff additionally plans to include further steel alloys equivalent to Inconel and copper. The analysis was supported by the Utilized Analysis Laboratory’s Walker Graduate Assistantship and the U.S. Nationwide Science Basis.

Supply: psu.edu